PCT test chamber

A Pressure Cooker Test (PCT) Chamber, also known as an Autoclave or Highly Accelerated Stress Test (HAST) Chamber, is an environmental test device used to rapidly evaluate the moisture resistance and long-term reliability of materials, components, and products.

A Pressure Cooker Test (PCT) Chamber, also known as an Autoclave or Highly Accelerated Stress Test (HAST) Chamber, is an environmental test device used to rapidly evaluate the moisture resistance and long-term reliability of materials, components, and products.

Core Applications are as following:

Semiconductors & Electronics: Testing IC packages, PCB assemblies, and seals for moisture ingress, corrosion, and "popcorn" delamination effects.

Automotive & Aerospace: Qualifying sensors, connectors, and control modules for resistance to humid, high-temperature conditions.

Materials Science: Evaluating adhesives, coatings, composites, and barrier films.

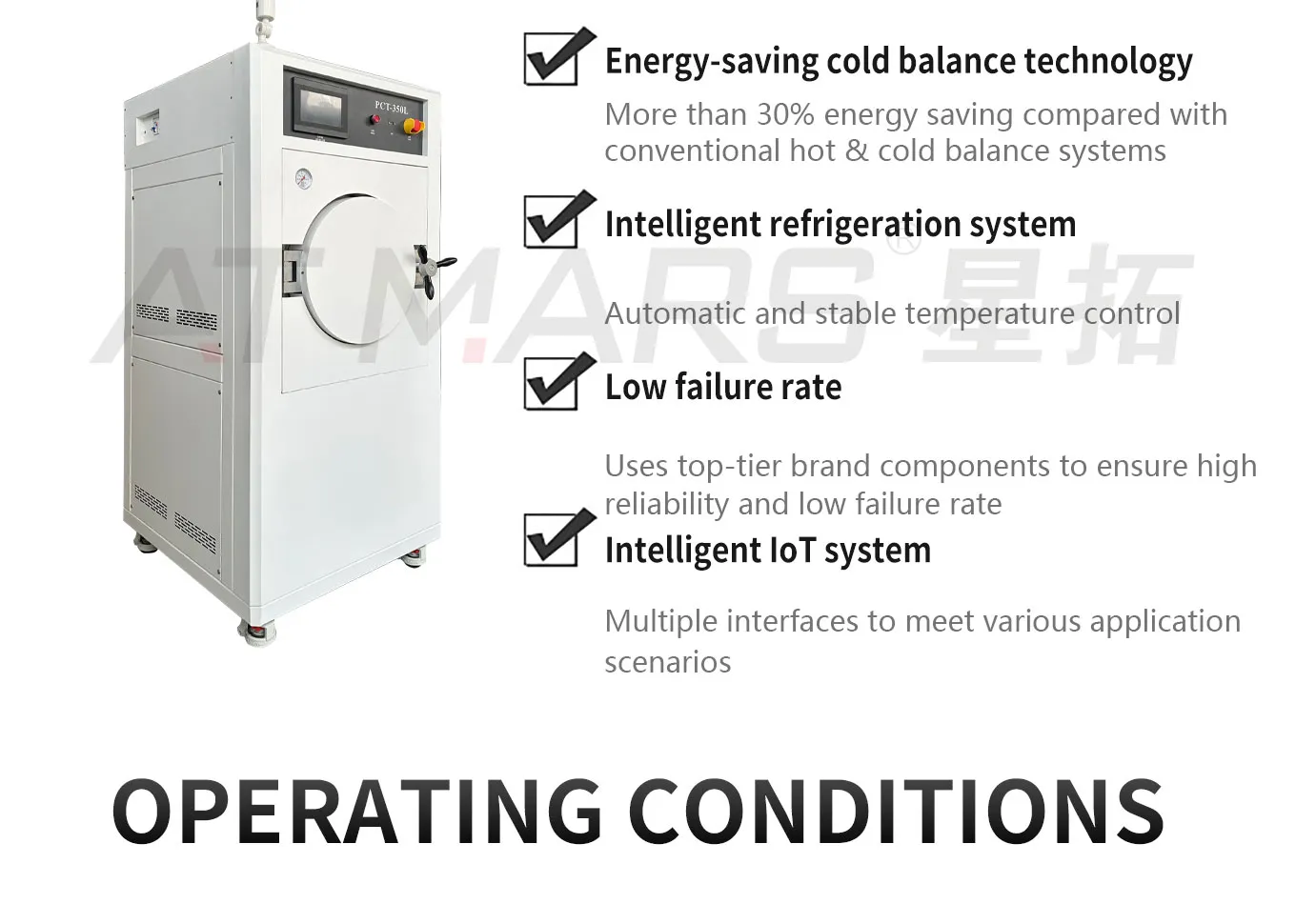

Core Advantages:

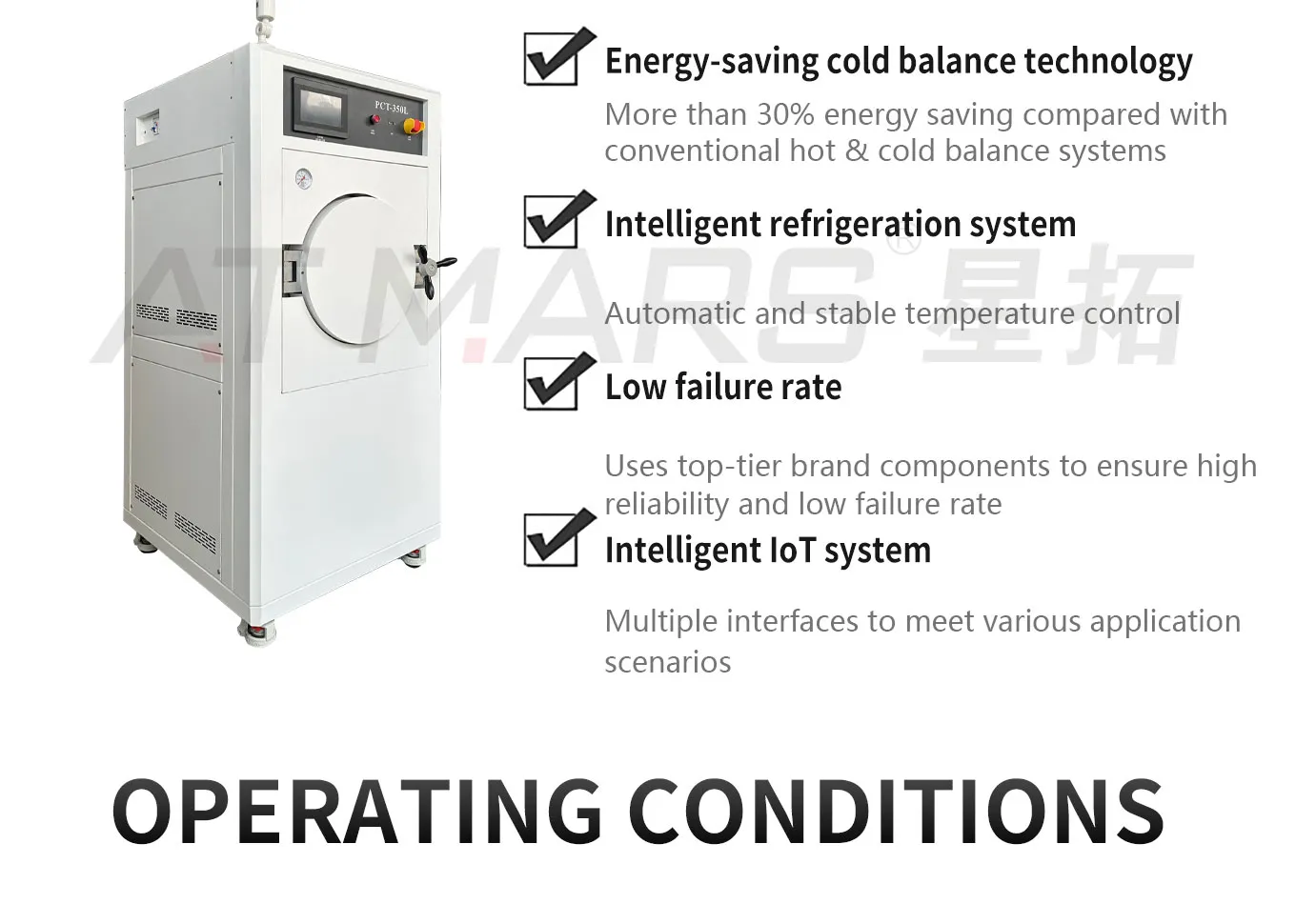

1. Unmatched Performance & Accuracy

Precision Control: Advanced multi-stage control algorithms ensure ultra-stable temperature, humidity, and pressure conditions (e.g., ±0.1°C, ±0.5% RH), guaranteeing that your accelerated test results are accurate, repeatable, and compliant with stringent standards like JESD22-A102, JESD22-A110, and MIL-STD.

Rapid Conditioning: Patented heating and pressurization systems achieve setpoint conditions faster, drastically reducing test cycle time and increasing lab throughput.

2. Legendary Durability & Chamber Integrity

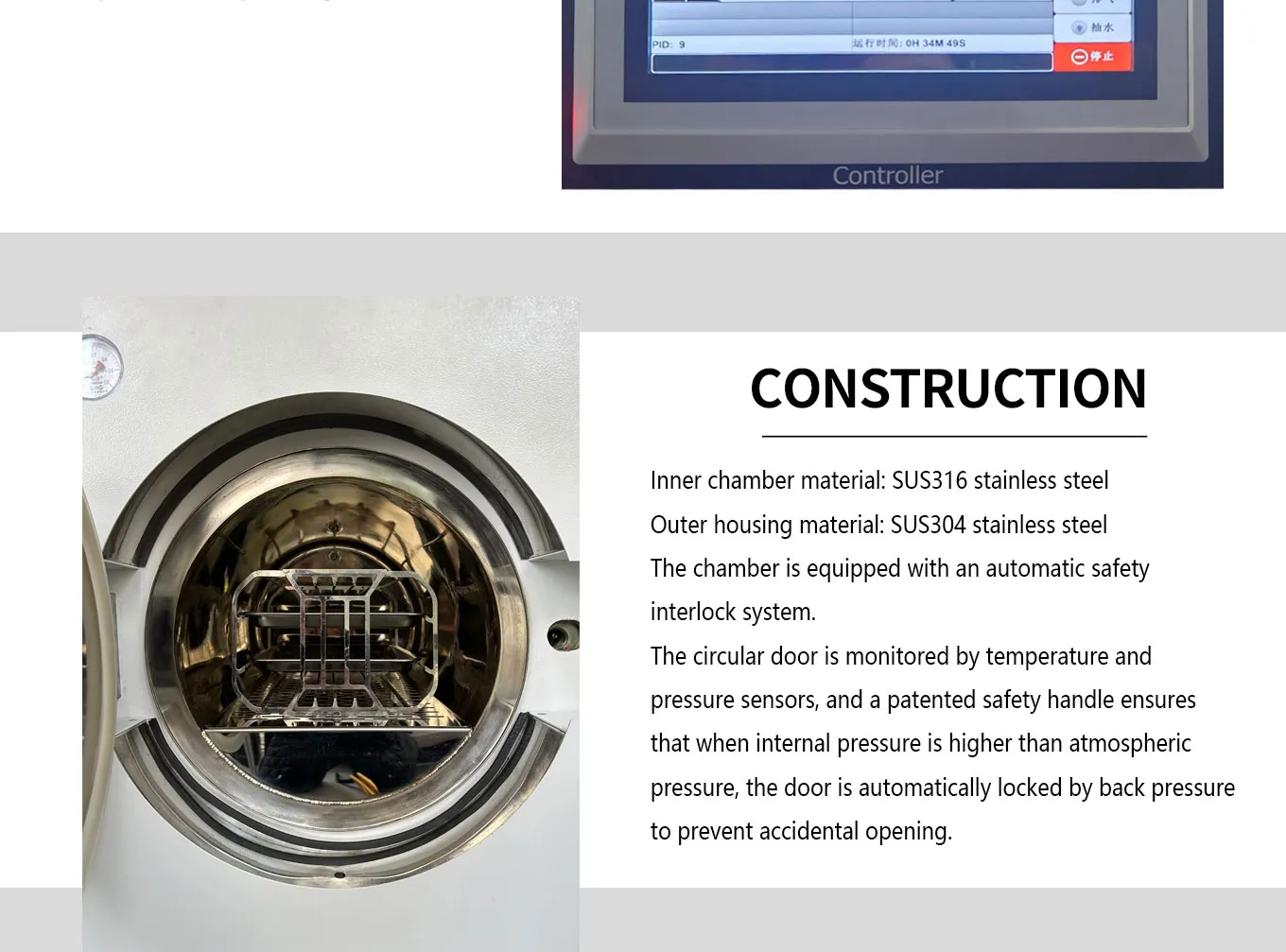

Corrosion-Resistant Architecture: We utilize premium 316L stainless steel for all critical wetted parts (chamber interior, water tank, steam generator), not just the liner. This provides superior resistance to deionized water and corrosive steam, extending chamber life by years and eliminating a primary point of failure in competitive models.

Robust Sealing Technology: Our proprietary door seal and clamping mechanism ensure perfect, maintenance-free seals even after tens of thousands of aggressive pressure cycles, preventing costly test invalidations due to leaks.

3. Intelligent Operation & Data Integrity

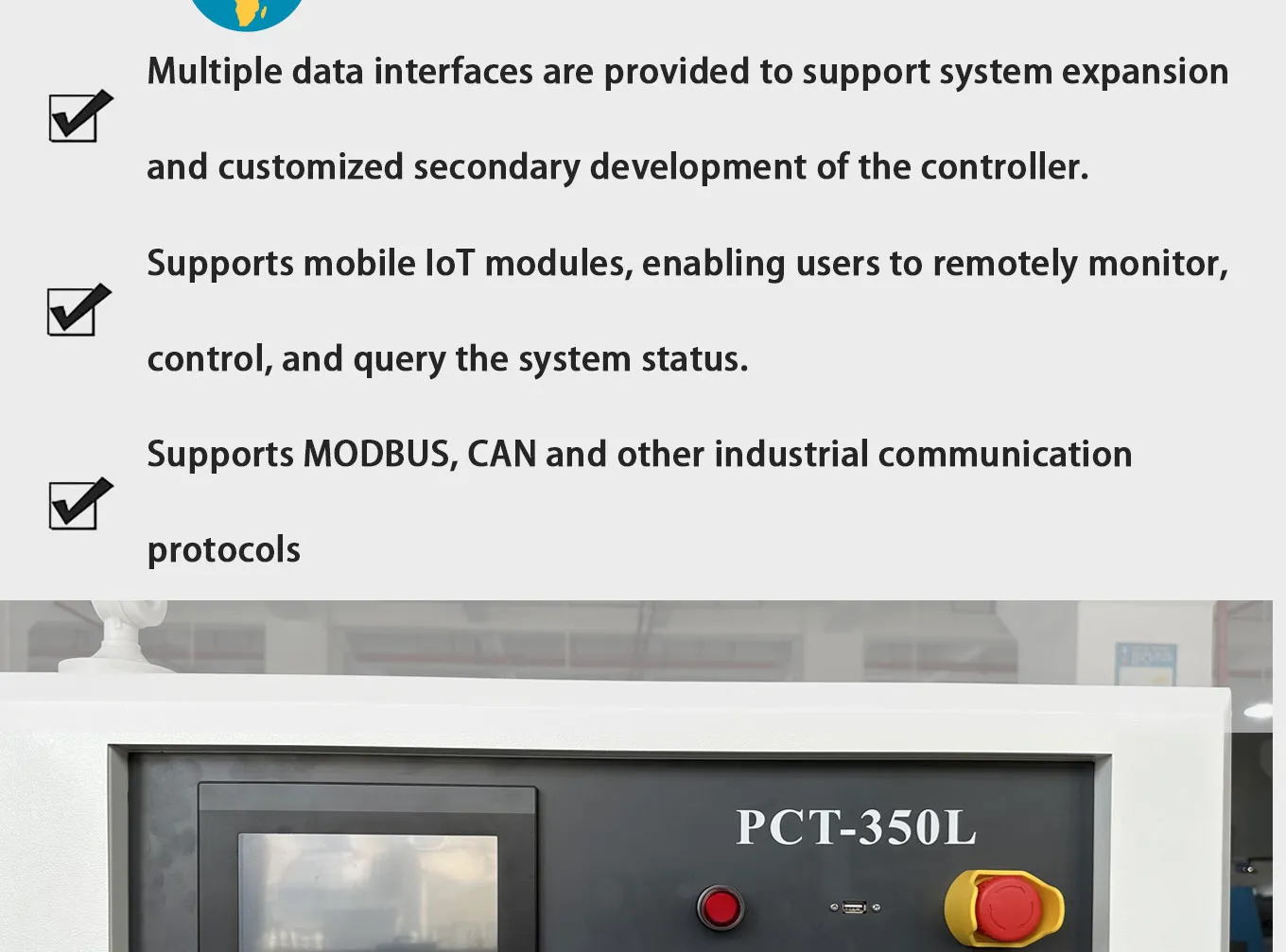

Intuitive Human-Machine Interface (HMI): A large touch-screen PLC controller offers simple programming of complex multi-segment test profiles, real-time graphing, and remote monitoring capabilities, minimizing operator error.

Comprehensive Safety & Data Logging: Built-in cascade alarms, automatic safety shut-offs, and detailed, audit-ready data logging protect both your valuable samples and your test records.

4. Engineered for Productivity

Low Maintenance Design: Features like automatic water replenishment, self-diagnostic systems, and easy-access components are standard, reducing downtime and total cost of ownership.

Flexible Configuration: Tailored solutions are available, including multiple chamber sizes, varying pressure ranges (up to 3 atm or higher), and integration options for additional monitoring or automation.

Many chambers may meet the specification, while Atmars chambers are engineered to survive the specification year after year. We build our PCT chambers to the same reliability standard that your products are being tested for. This results in lower lifetime cost, higher confidence in test data, and a testing foundation you can depend on for critical qualification, failure analysis, and R&D.

Core Applications are as following:

Semiconductors & Electronics: Testing IC packages, PCB assemblies, and seals for moisture ingress, corrosion, and "popcorn" delamination effects.

Automotive & Aerospace: Qualifying sensors, connectors, and control modules for resistance to humid, high-temperature conditions.

Materials Science: Evaluating adhesives, coatings, composites, and barrier films.

Core Advantages:

1. Unmatched Performance & Accuracy

Precision Control: Advanced multi-stage control algorithms ensure ultra-stable temperature, humidity, and pressure conditions (e.g., ±0.1°C, ±0.5% RH), guaranteeing that your accelerated test results are accurate, repeatable, and compliant with stringent standards like JESD22-A102, JESD22-A110, and MIL-STD.

Rapid Conditioning: Patented heating and pressurization systems achieve setpoint conditions faster, drastically reducing test cycle time and increasing lab throughput.

2. Legendary Durability & Chamber Integrity

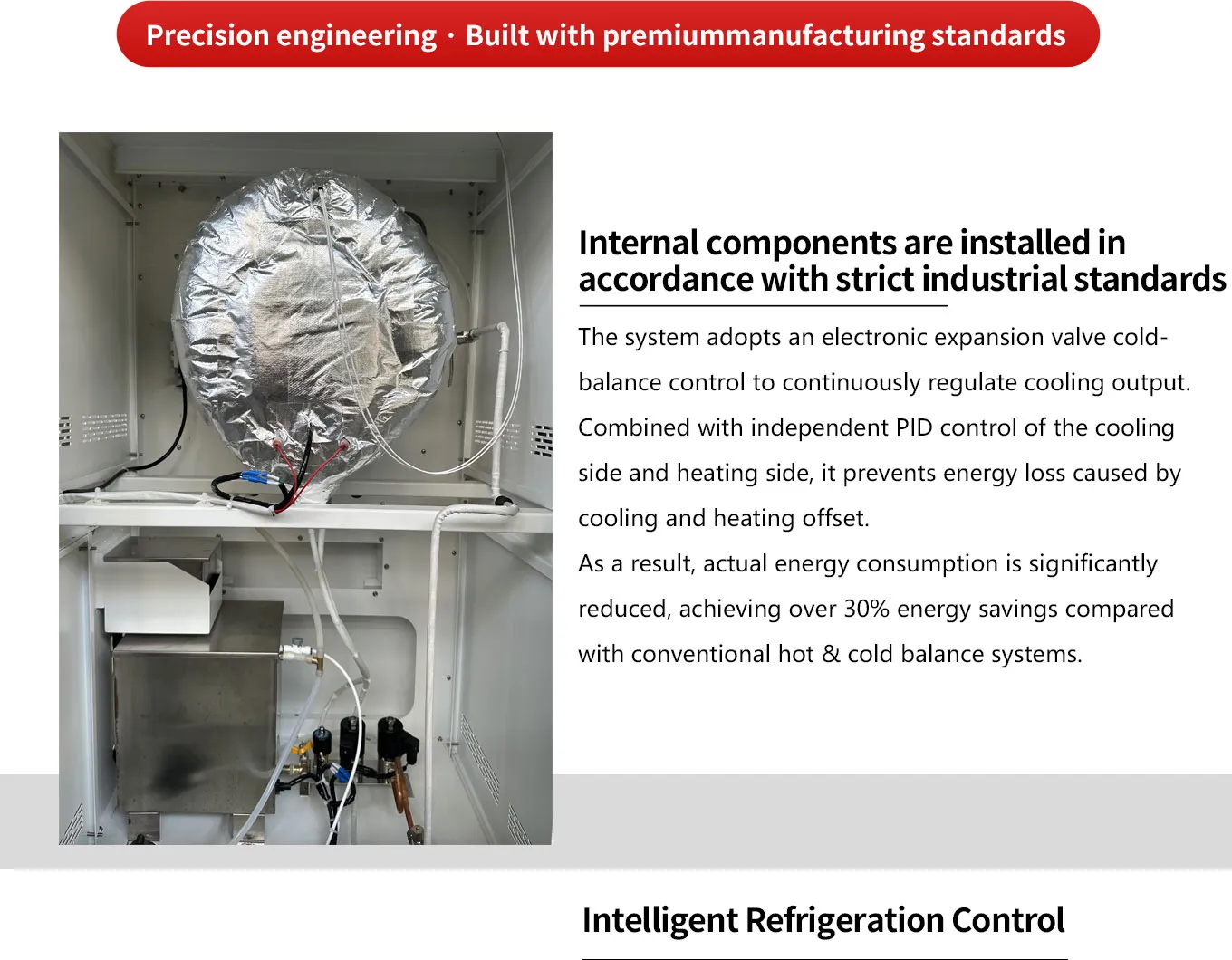

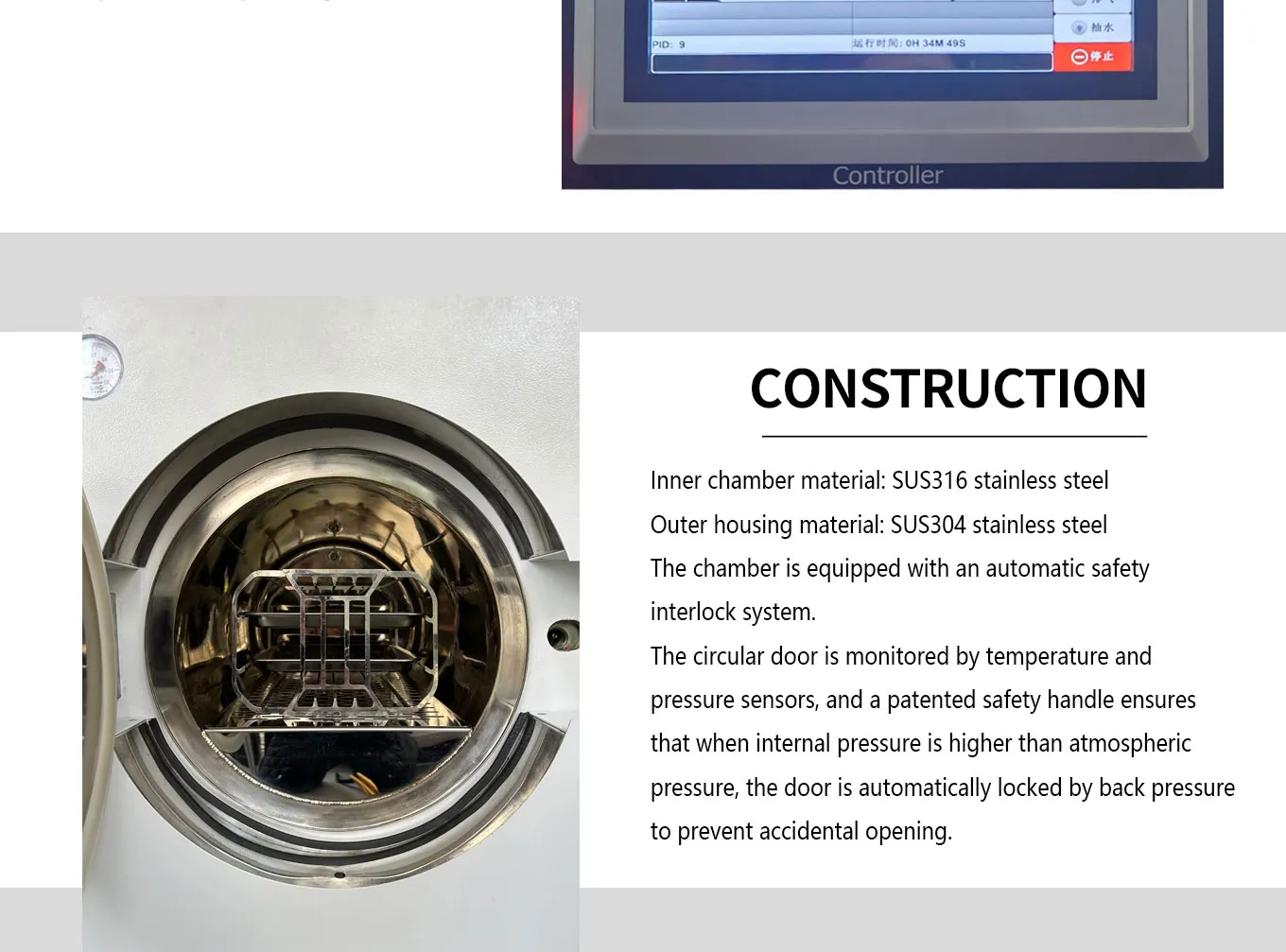

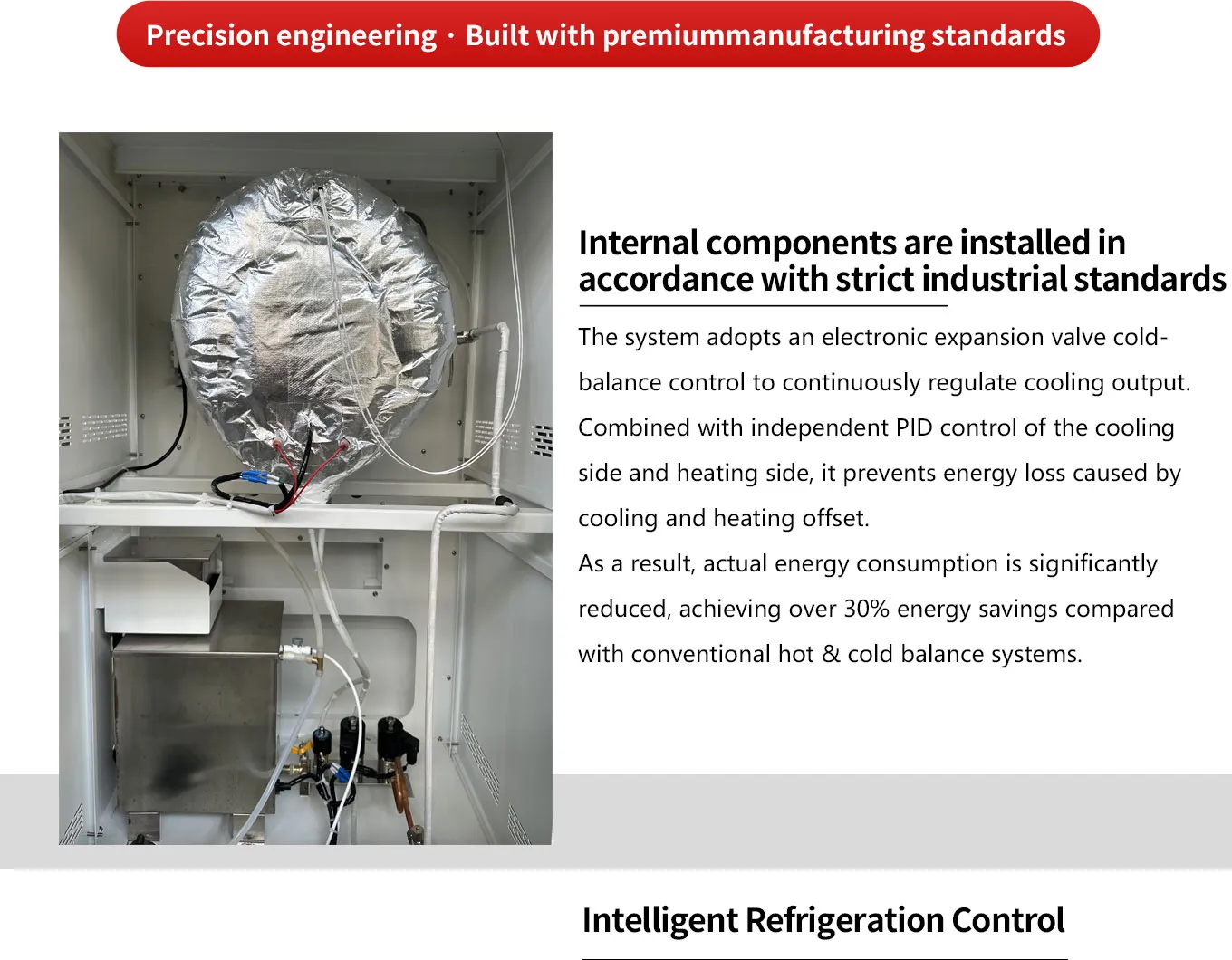

Corrosion-Resistant Architecture: We utilize premium 316L stainless steel for all critical wetted parts (chamber interior, water tank, steam generator), not just the liner. This provides superior resistance to deionized water and corrosive steam, extending chamber life by years and eliminating a primary point of failure in competitive models.

Robust Sealing Technology: Our proprietary door seal and clamping mechanism ensure perfect, maintenance-free seals even after tens of thousands of aggressive pressure cycles, preventing costly test invalidations due to leaks.

3. Intelligent Operation & Data Integrity

Intuitive Human-Machine Interface (HMI): A large touch-screen PLC controller offers simple programming of complex multi-segment test profiles, real-time graphing, and remote monitoring capabilities, minimizing operator error.

Comprehensive Safety & Data Logging: Built-in cascade alarms, automatic safety shut-offs, and detailed, audit-ready data logging protect both your valuable samples and your test records.

4. Engineered for Productivity

Low Maintenance Design: Features like automatic water replenishment, self-diagnostic systems, and easy-access components are standard, reducing downtime and total cost of ownership.

Flexible Configuration: Tailored solutions are available, including multiple chamber sizes, varying pressure ranges (up to 3 atm or higher), and integration options for additional monitoring or automation.

Many chambers may meet the specification, while Atmars chambers are engineered to survive the specification year after year. We build our PCT chambers to the same reliability standard that your products are being tested for. This results in lower lifetime cost, higher confidence in test data, and a testing foundation you can depend on for critical qualification, failure analysis, and R&D.