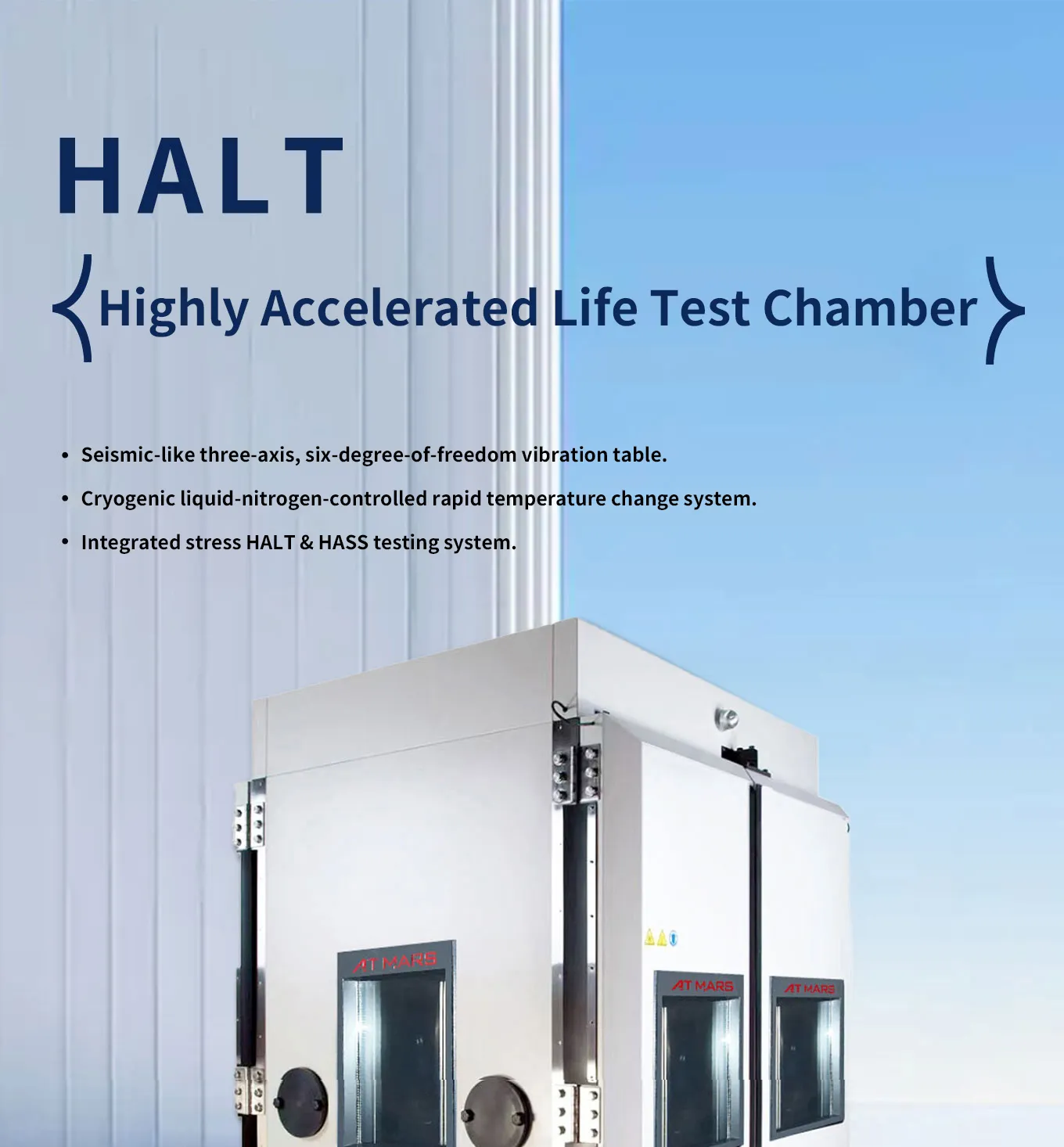

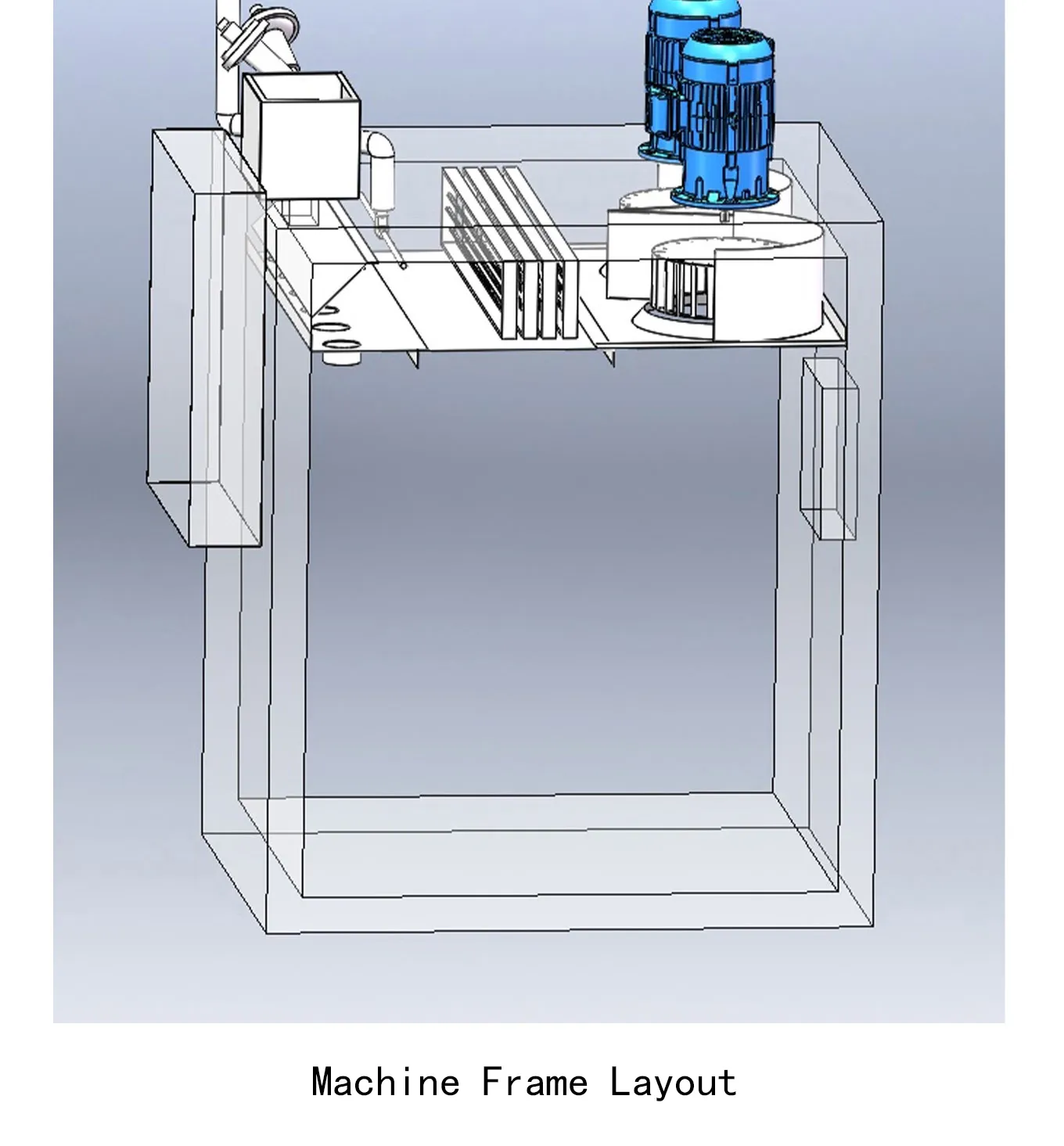

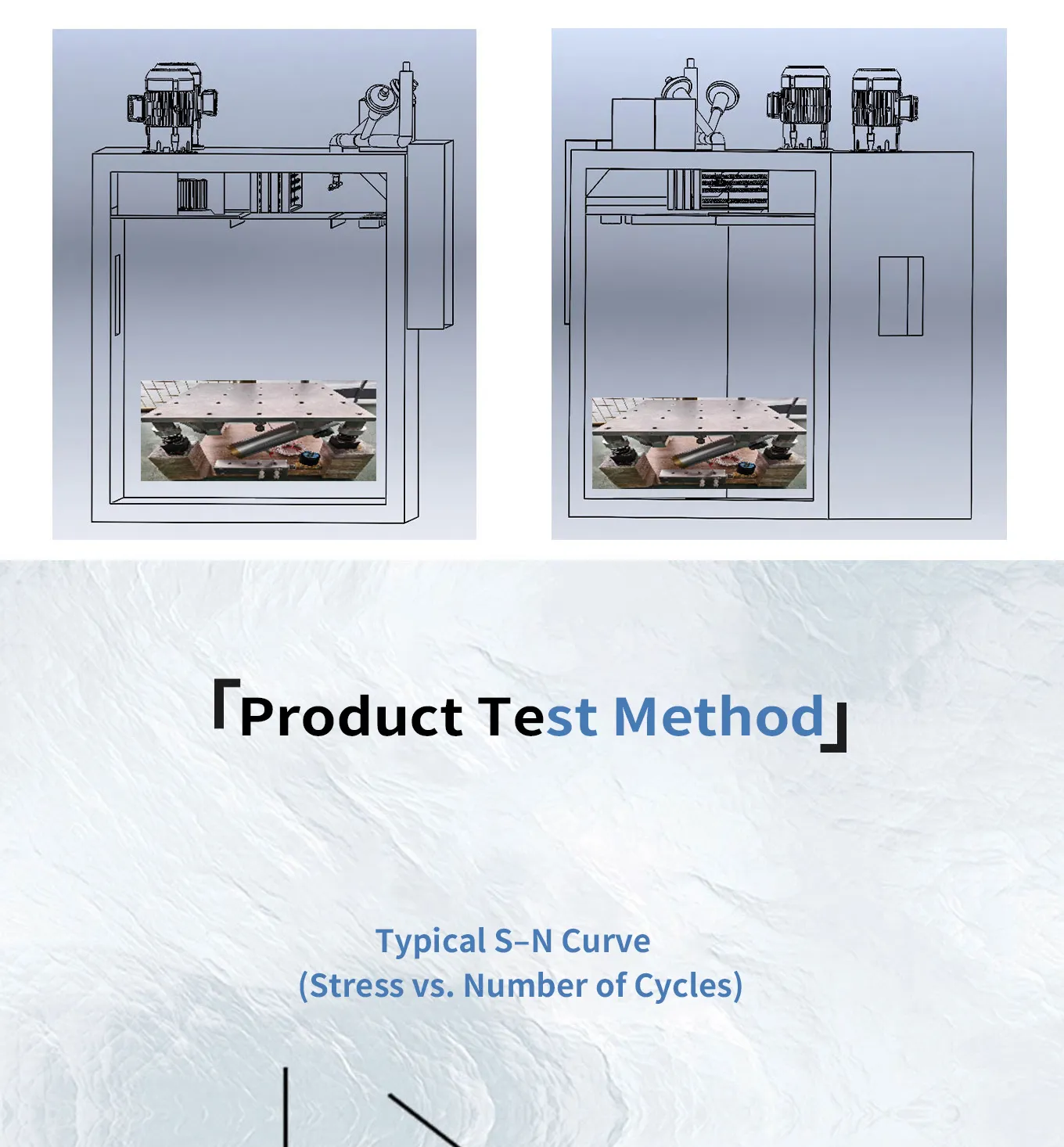

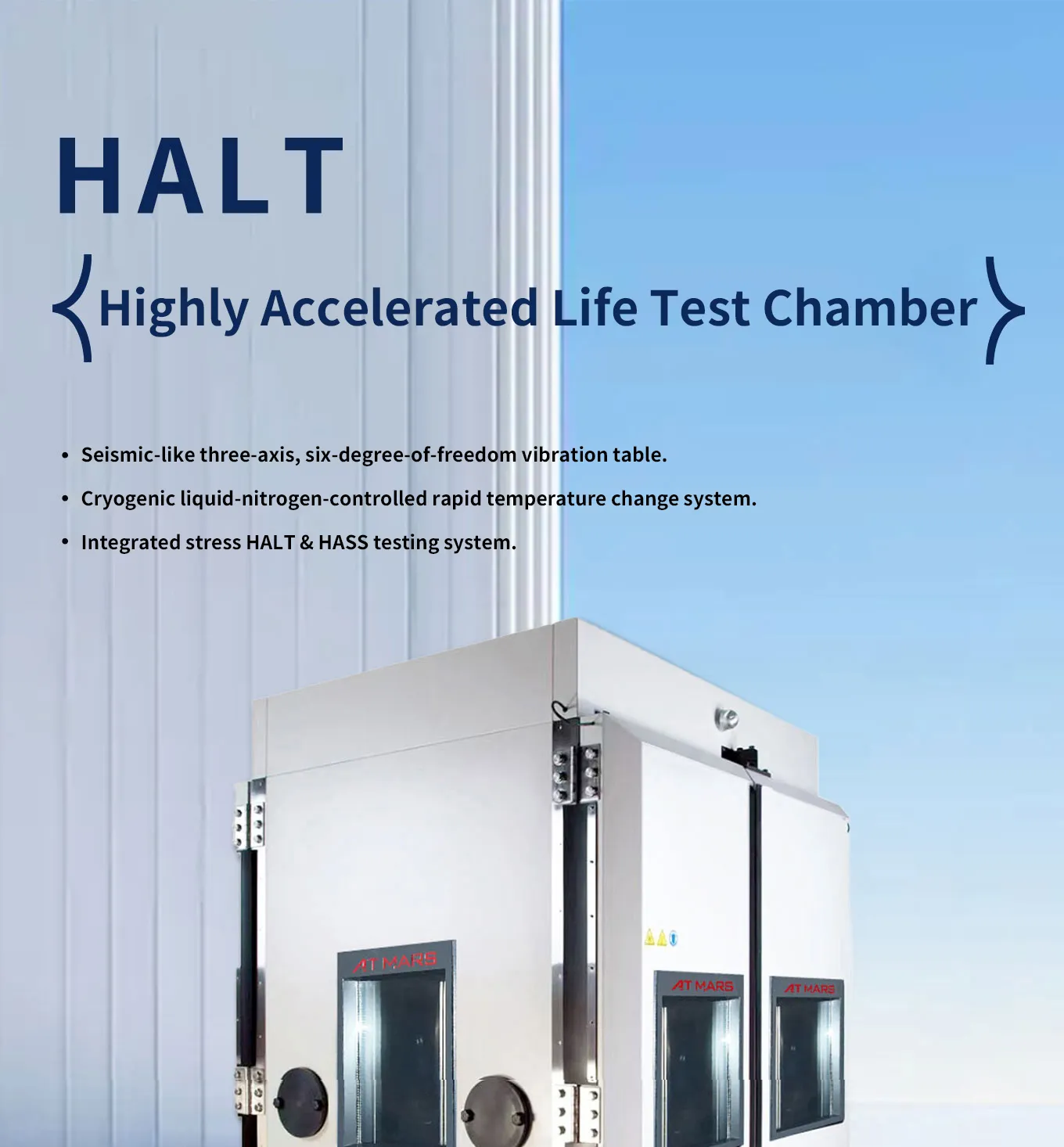

HALT test chamber

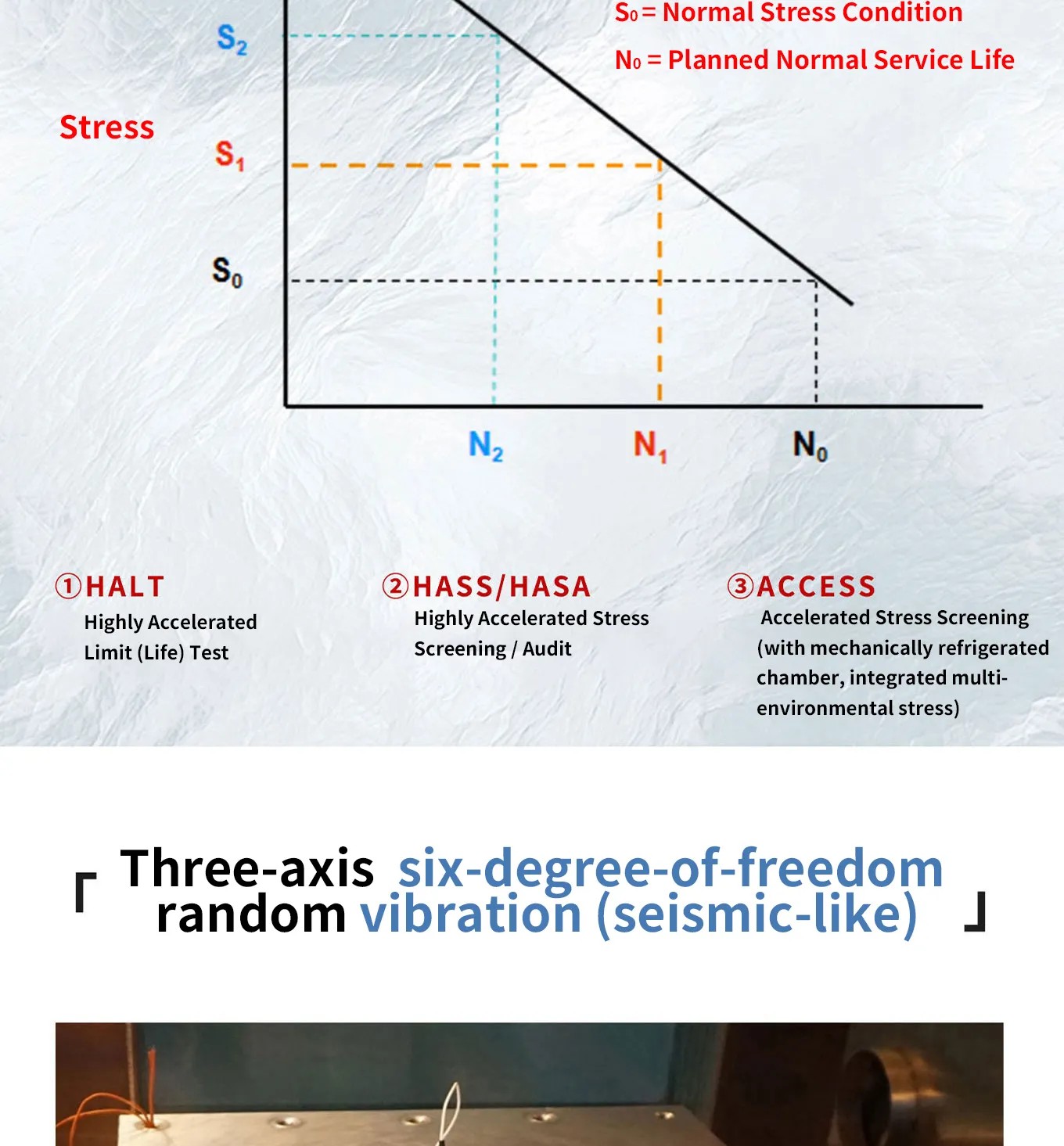

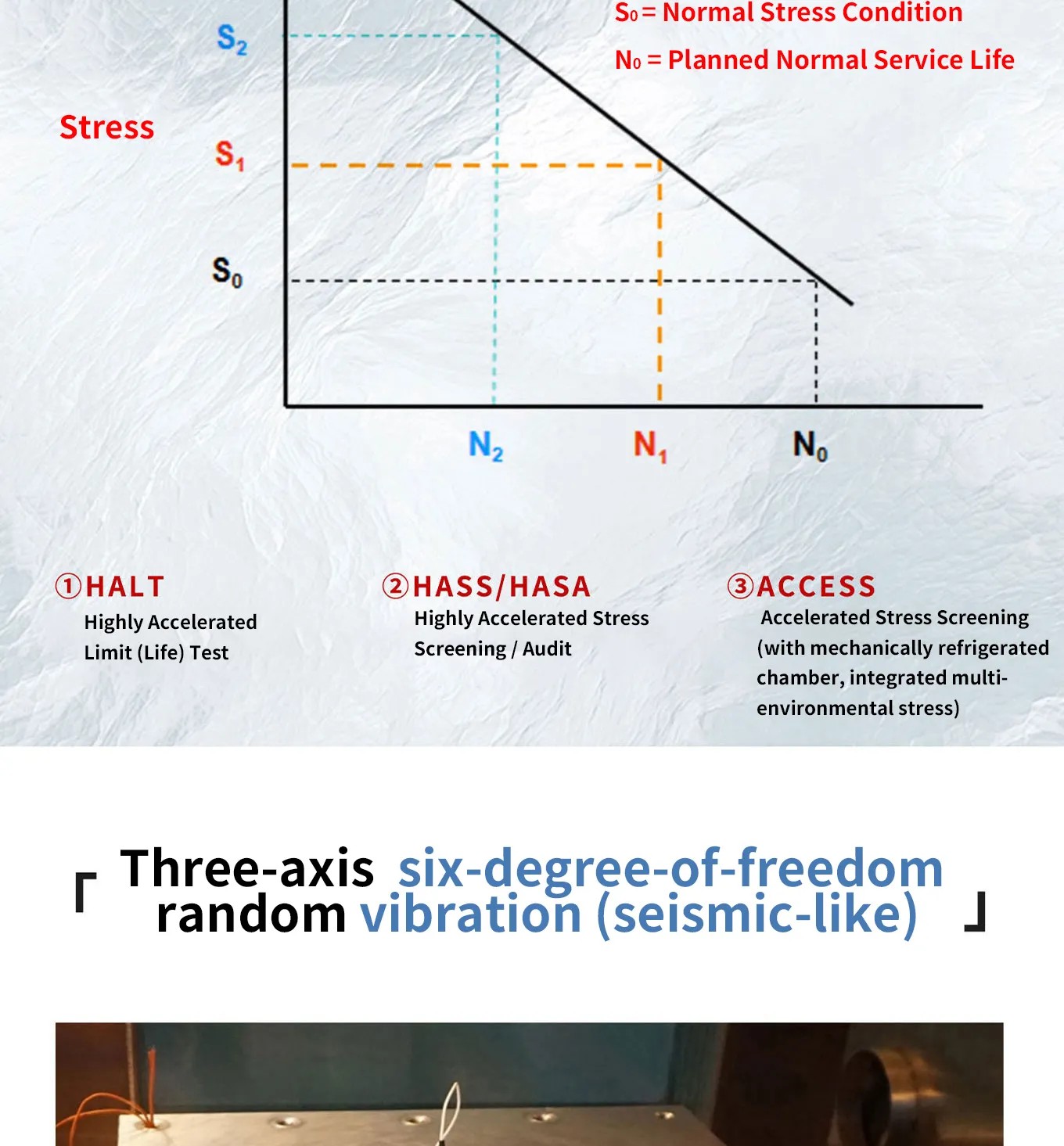

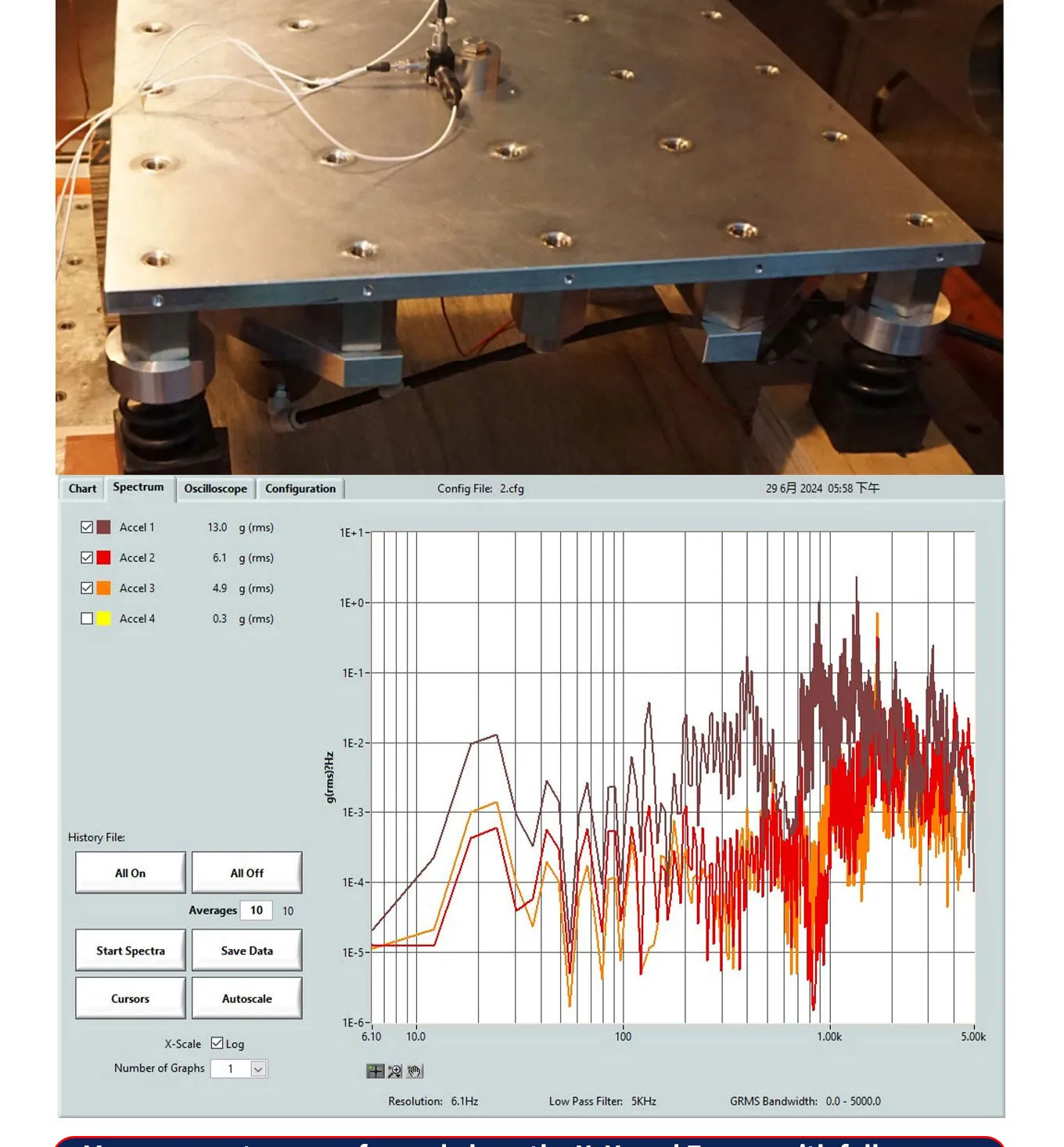

As a cutting-edge reliability testing solution, the HALT High-Pressure Accelerated Life Test Chamber is engineered to simulate extreme environmental conditions in a controlled lab setting. It accelerates the exposure of products to high pressure, temperature cycling, vibration, and other stress factors, enabling manufacturers to quickly identify potential design flaws, material weaknesses, and performance limits of components or finished products. Compared with conventional life tests, HALT chambers drastically shorten test cycles, reduce R&D costs, and help enterprises launch more durable and reliable products to the market with confidence.

As a cutting-edge reliability testing solution, the HALT High-Pressure Accelerated Life Test Chamber is engineered to simulate extreme environmental conditions in a controlled lab setting. It accelerates the exposure of products to high pressure, temperature cycling, vibration, and other stress factors, enabling manufacturers to quickly identify potential design flaws, material weaknesses, and performance limits of components or finished products. Compared with conventional life tests, HALT chambers drastically shorten test cycles, reduce R&D costs, and help enterprises launch more durable and reliable products to the market with confidence.

Core Advantages of HALT High-Pressure Accelerated Life Test Chamber

-

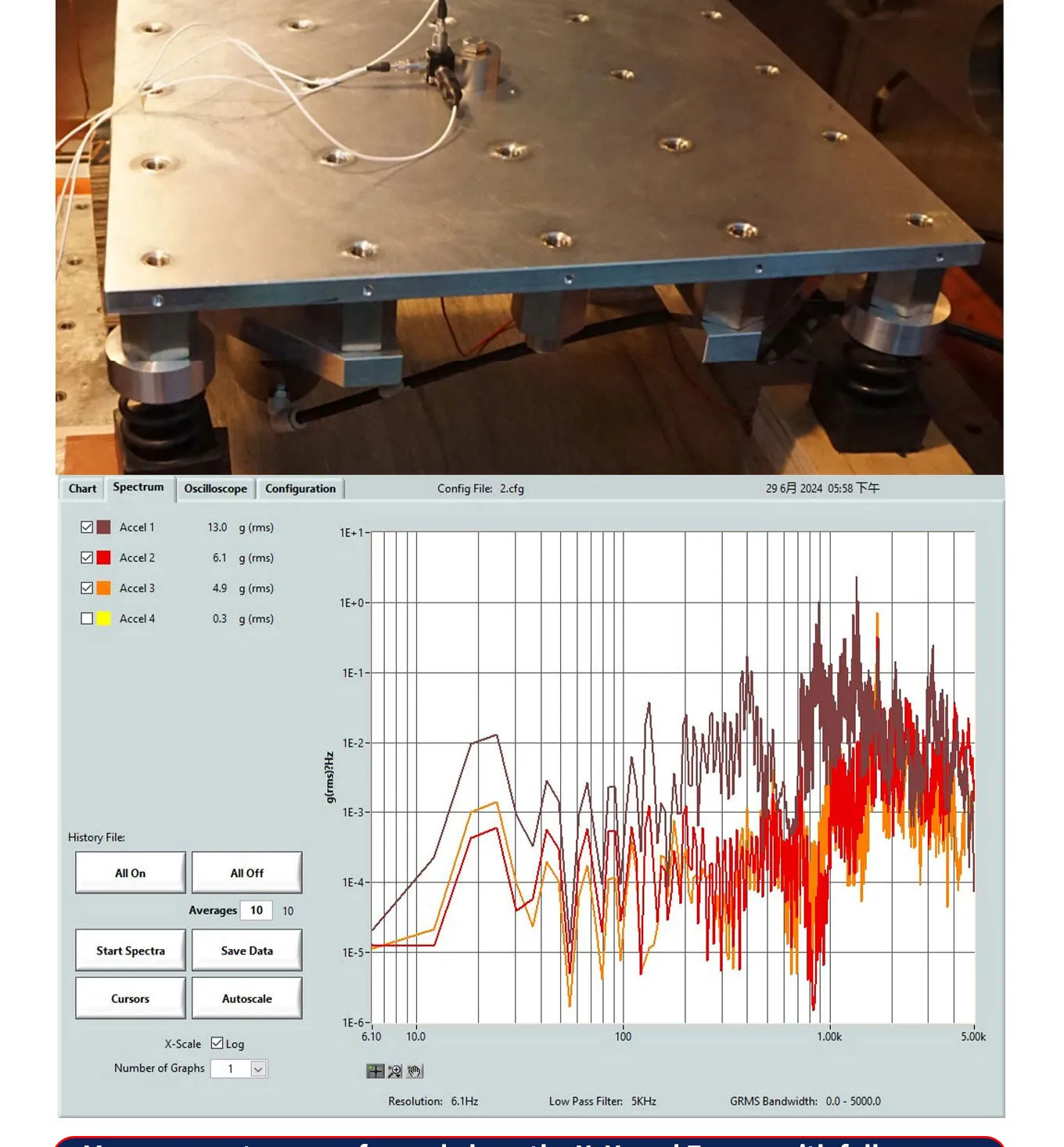

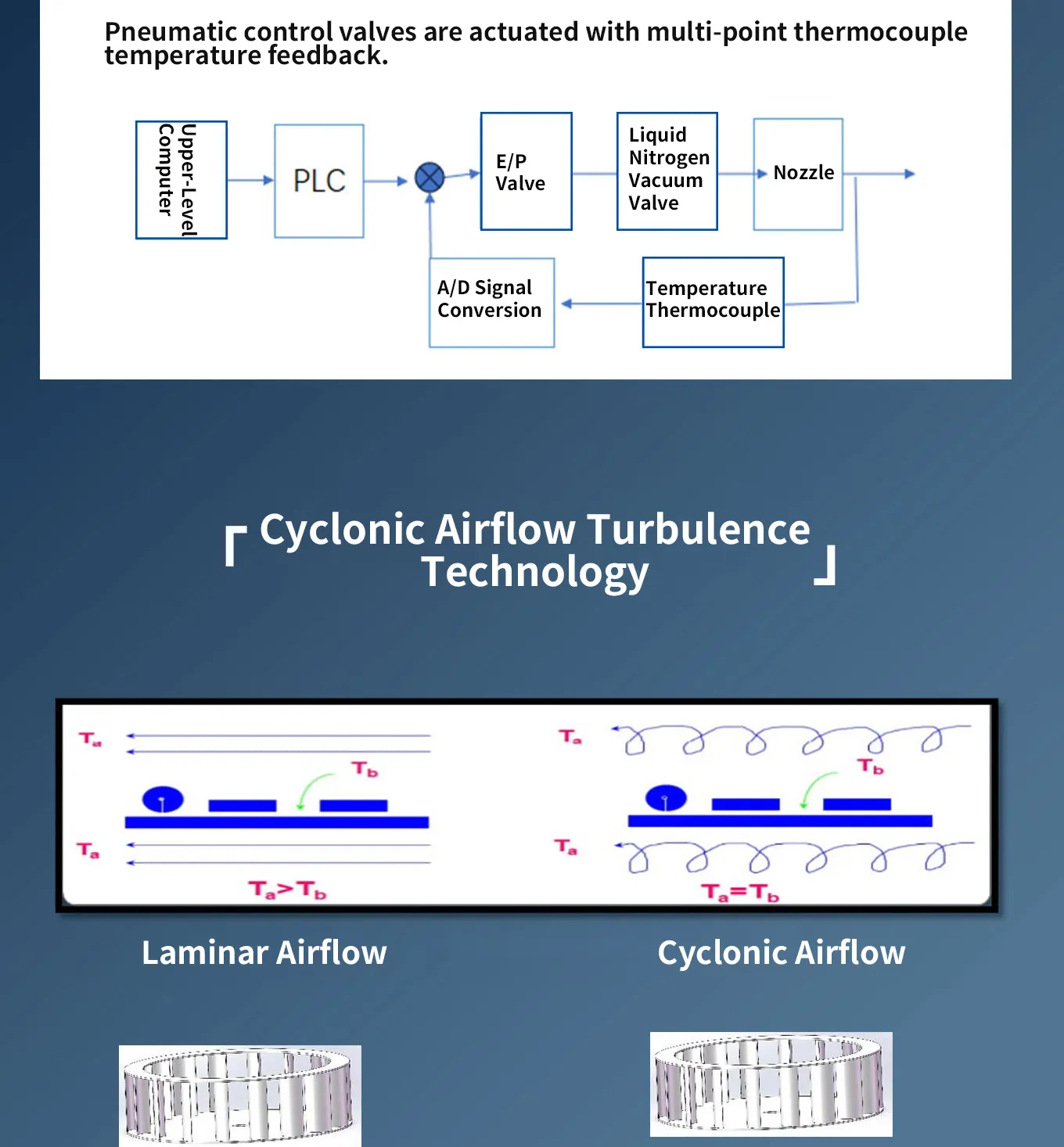

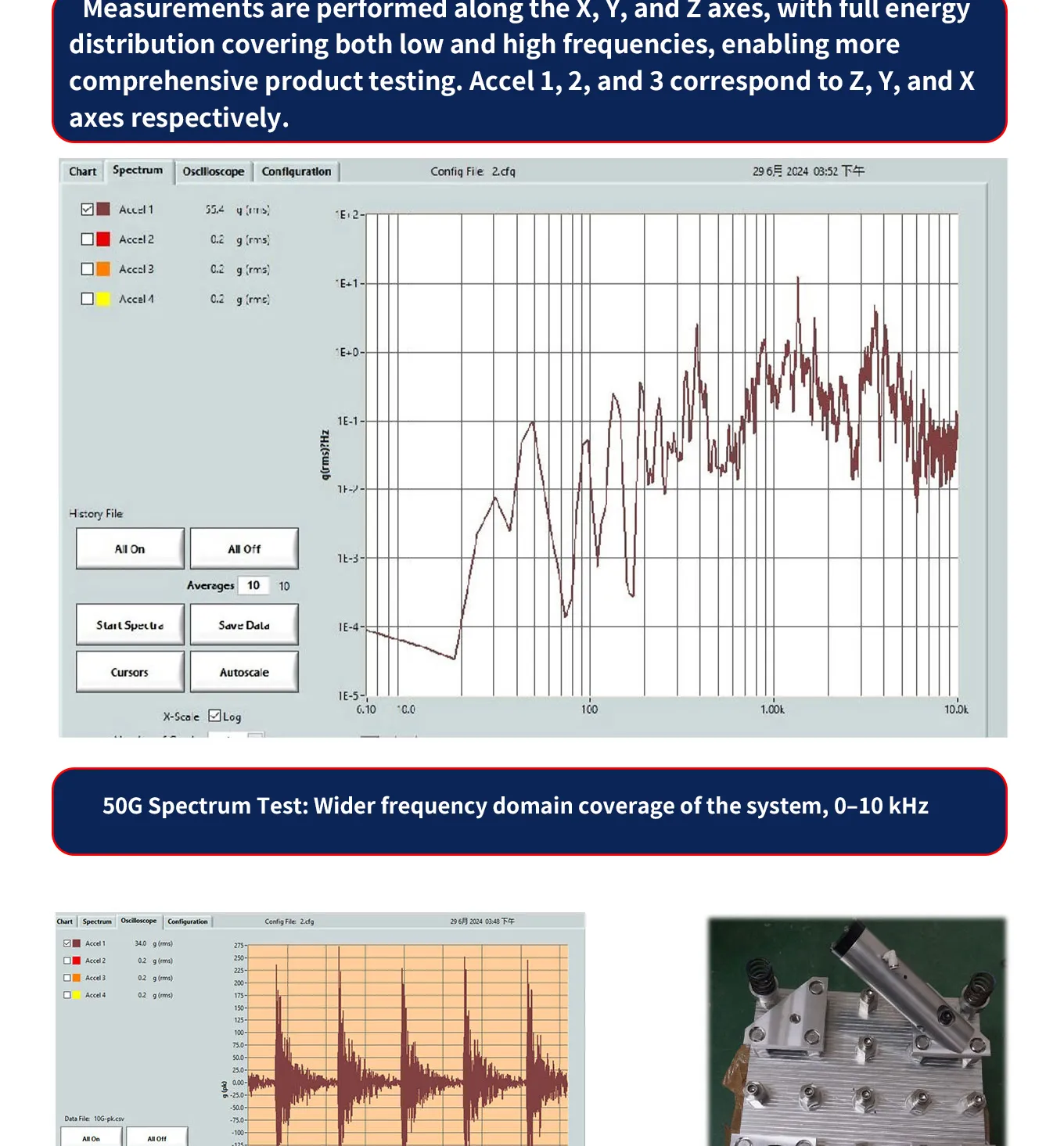

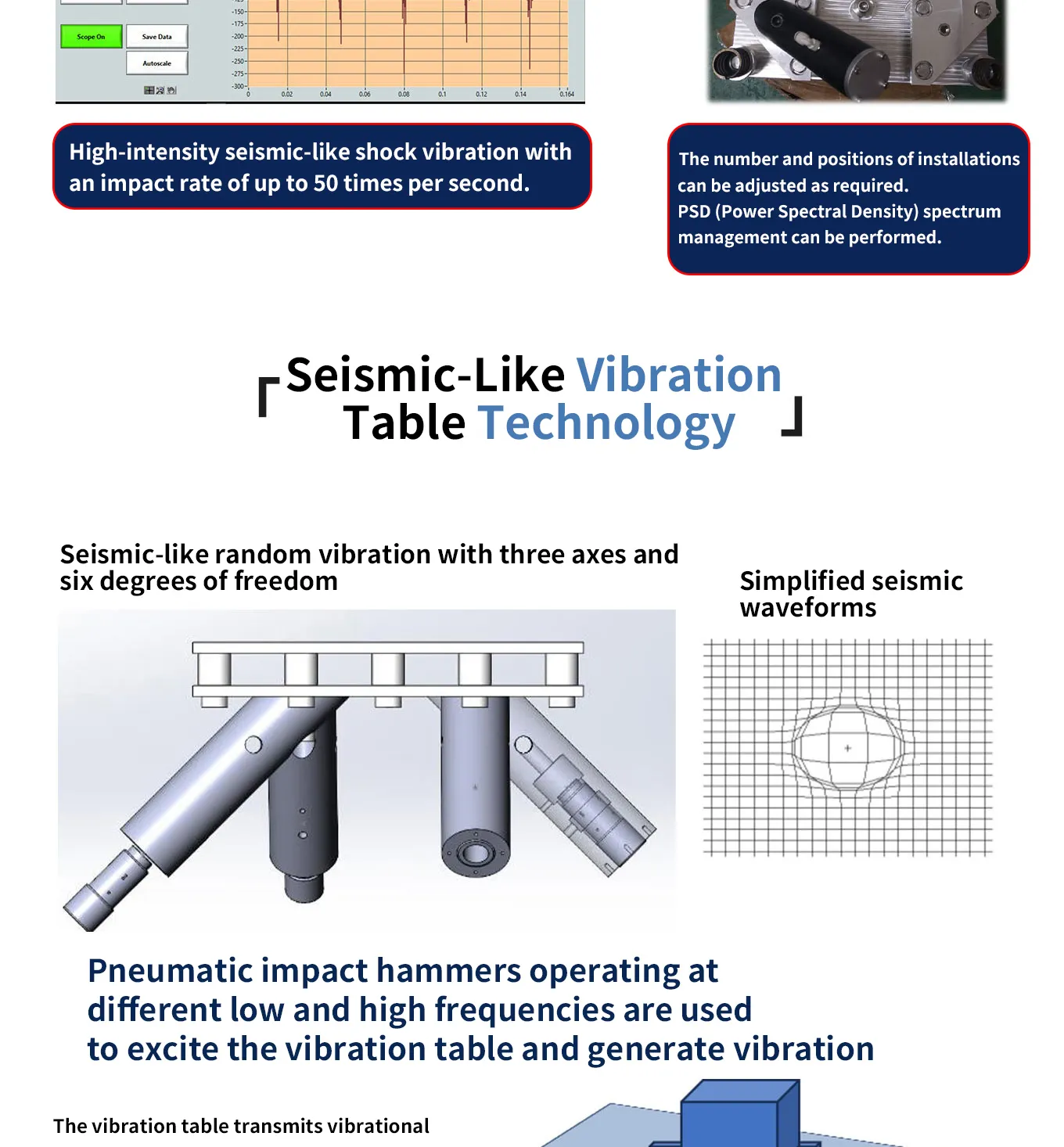

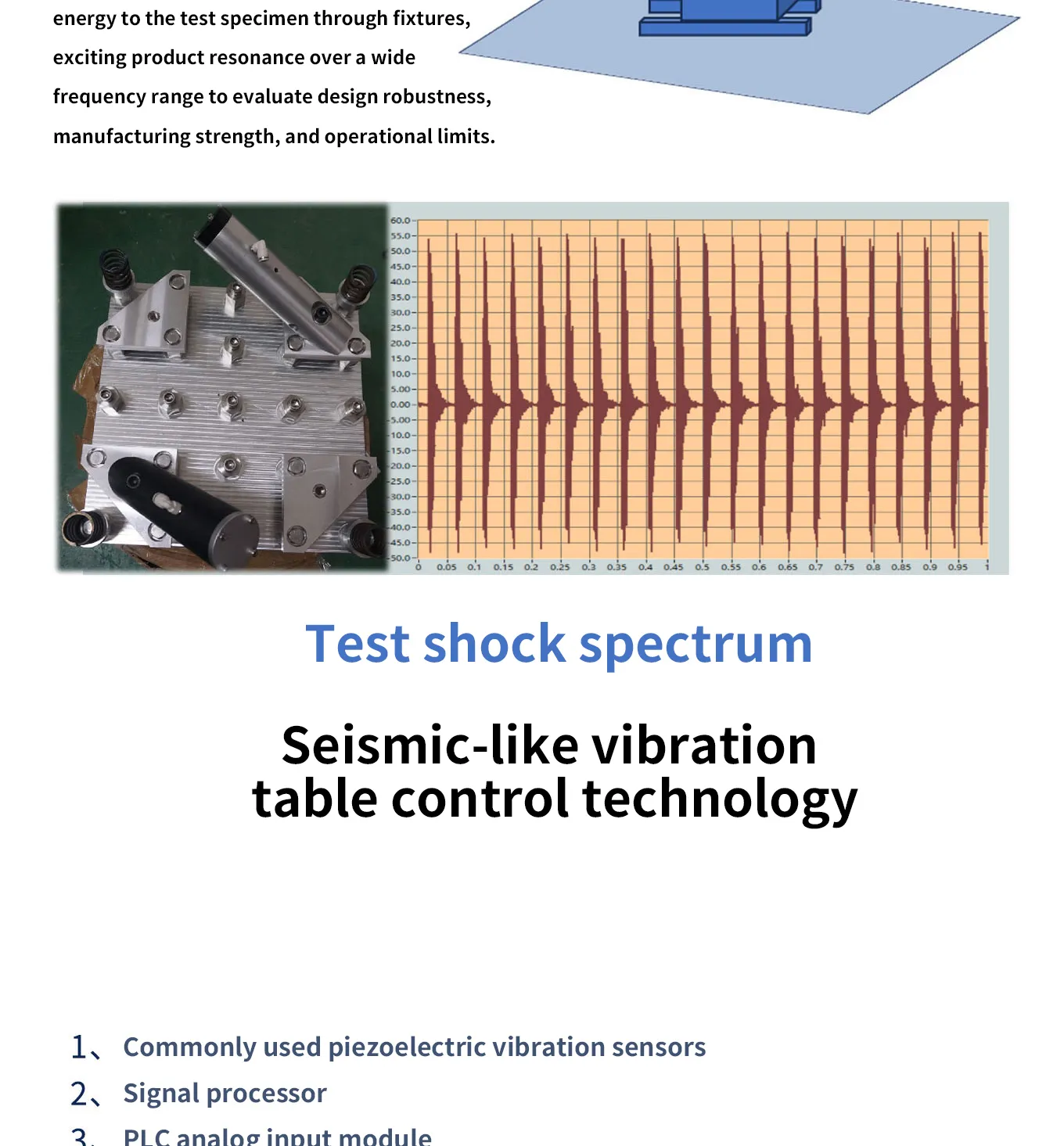

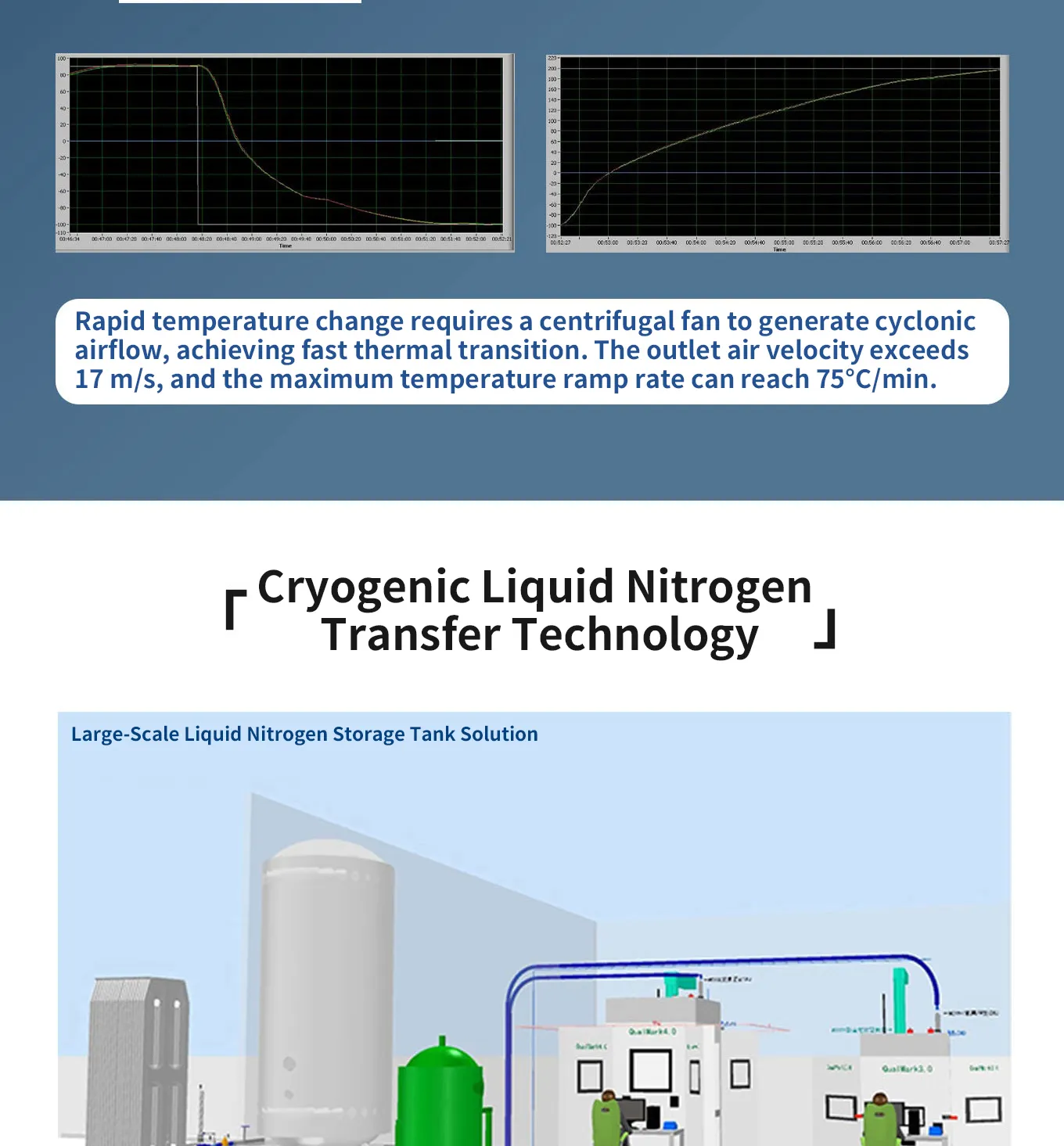

Ultra-Fast Failure Detection with Multi-Stress IntegrationThe chamber integrates multiple stress factors including high pressure, rapid temperature change, thermal shock, and vibration, which can simulate the cumulative impact of complex real-world environments on products. This multi-stress coupling technology accelerates the emergence of latent defects by 50–90% faster than single-factor tests, allowing R&D teams to locate design vulnerabilities in days instead of months.

-

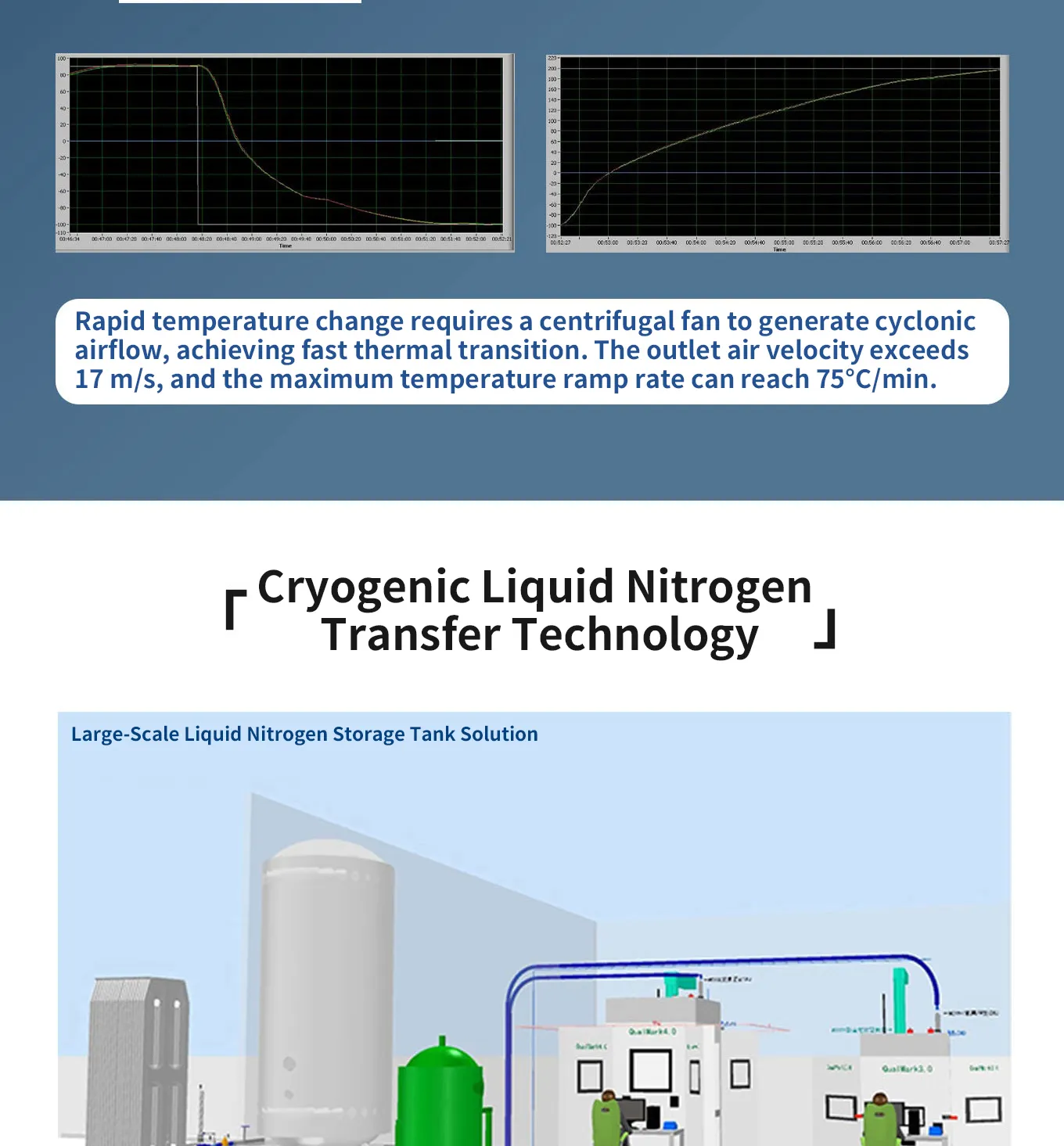

High-Pressure Environment Simulation for Special Industry NeedsEquipped with a precision pressure control system, it can simulate high-pressure scenarios ranging from 0.1 MPa to 10 MPa (customizable according to demands). This feature is particularly tailored for products applied in deep-sea exploration, aerospace, and high-pressure pipeline equipment, ensuring the test results are highly consistent with the actual working conditions of such products.

-

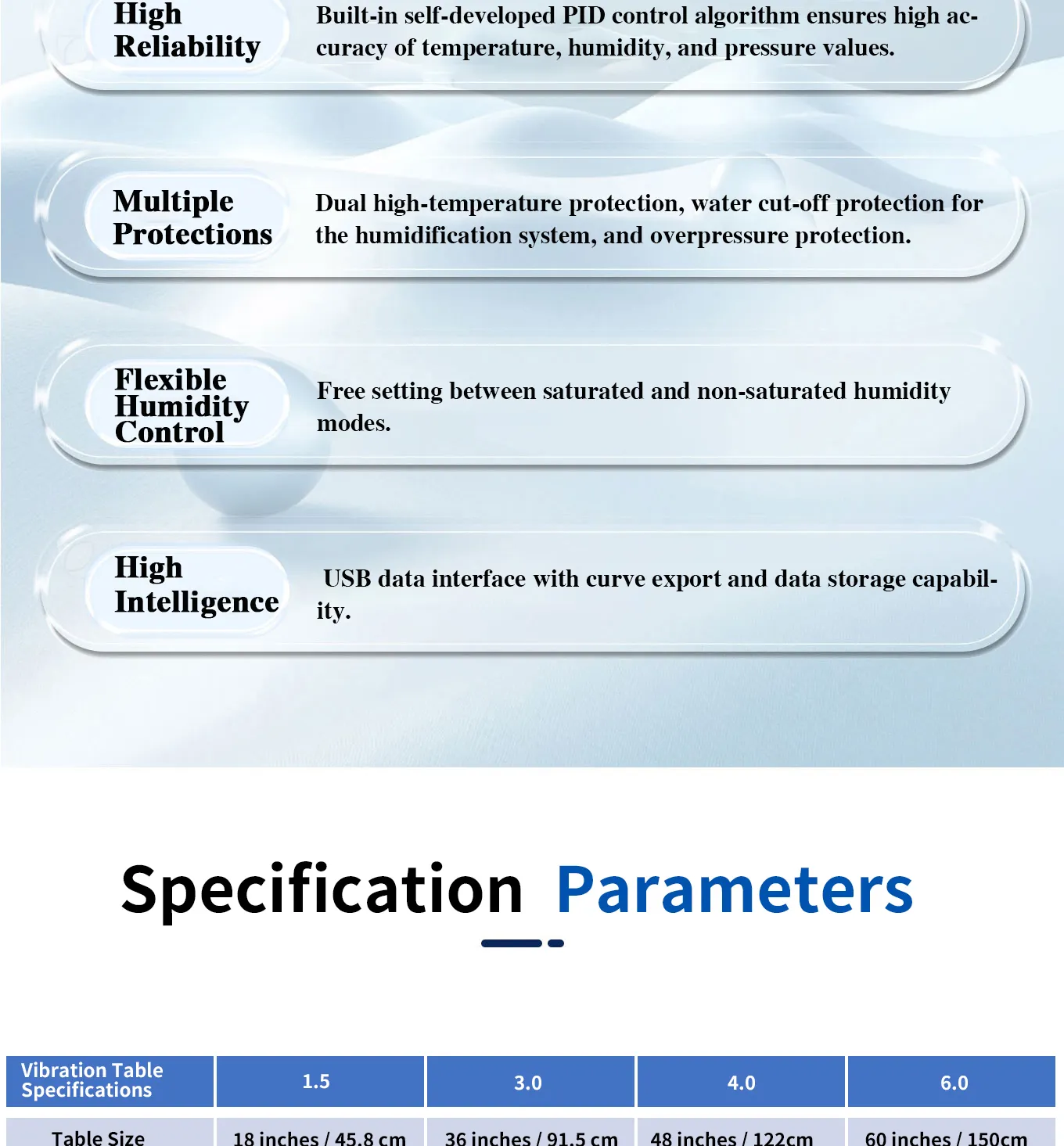

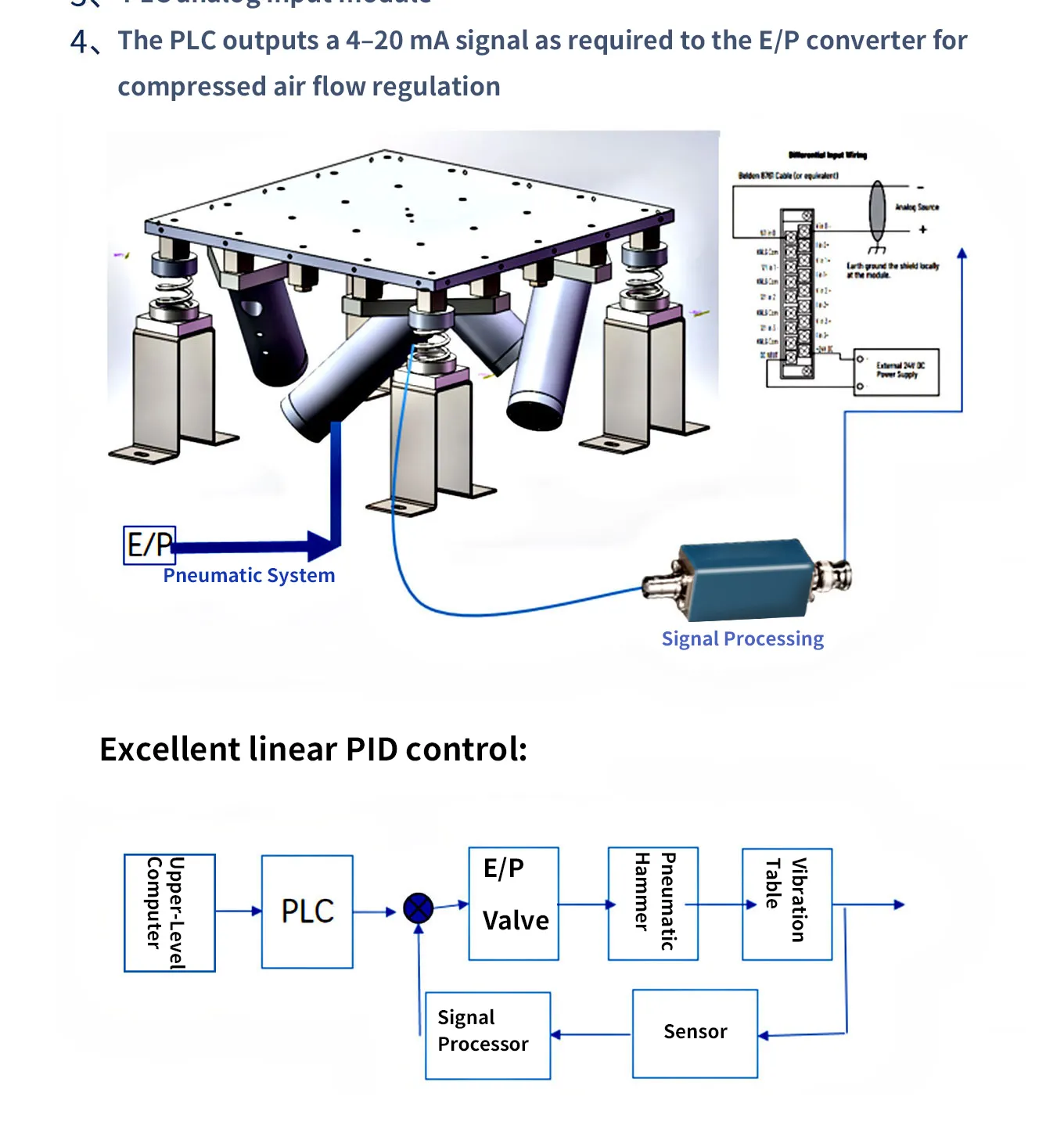

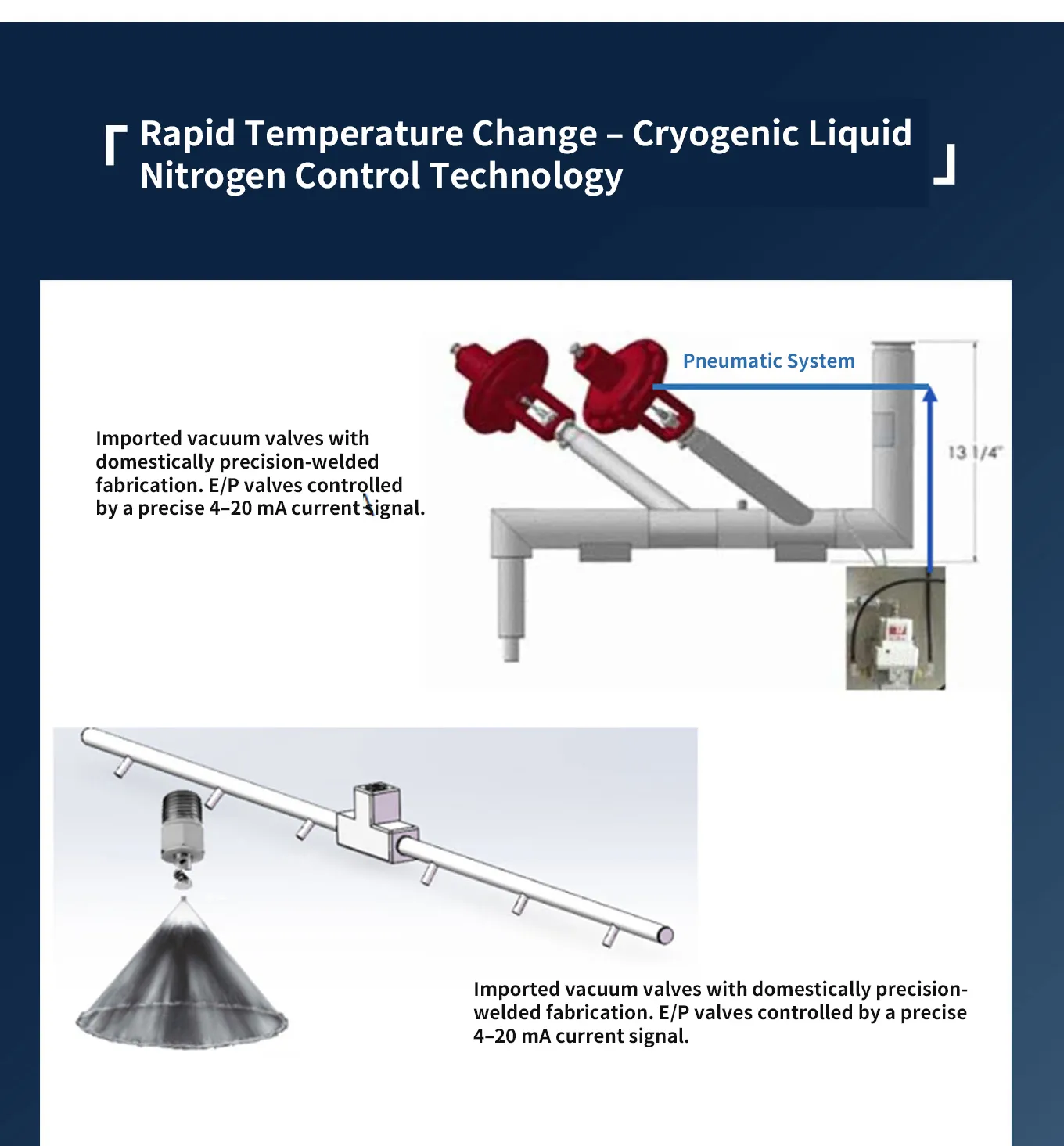

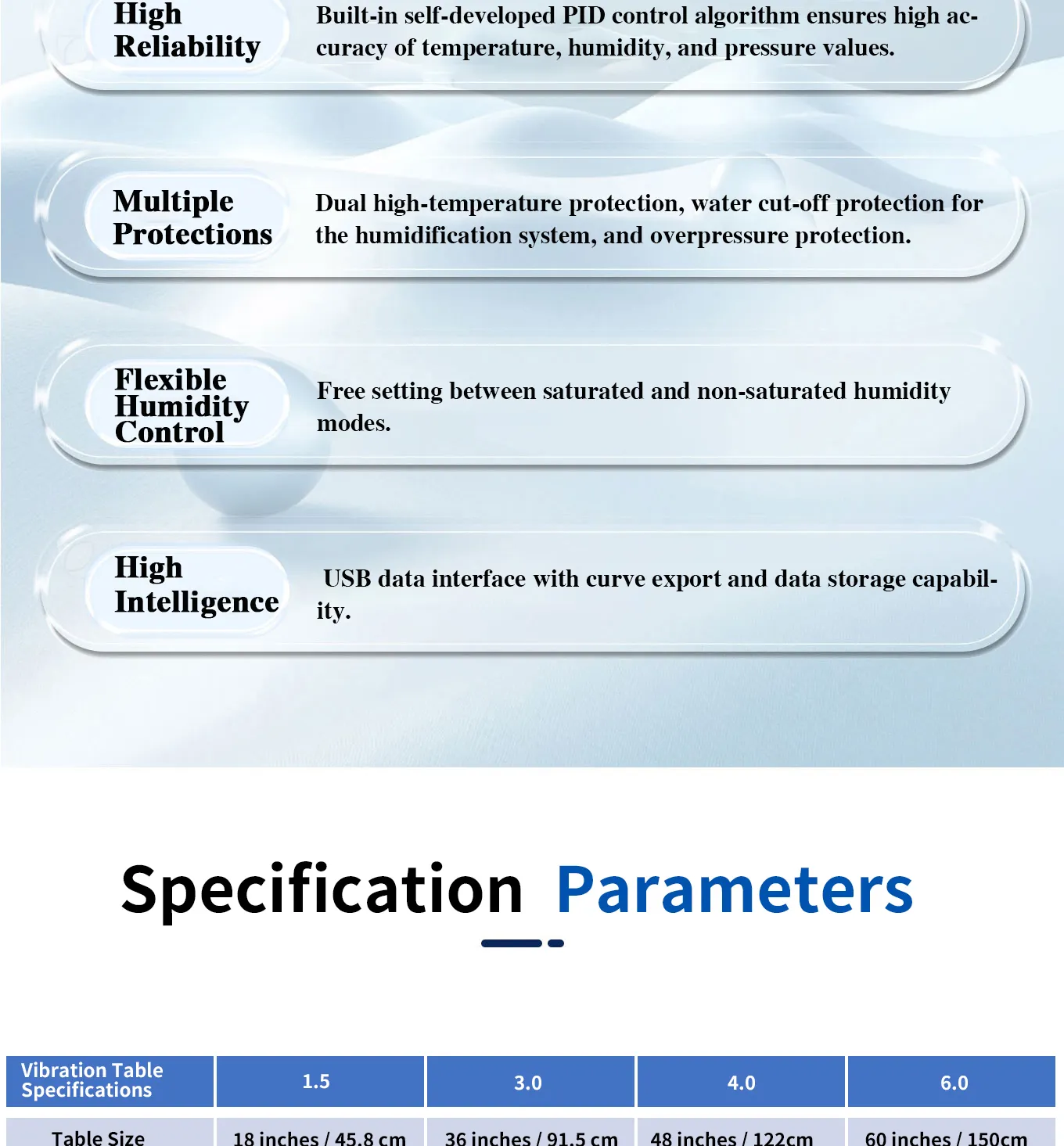

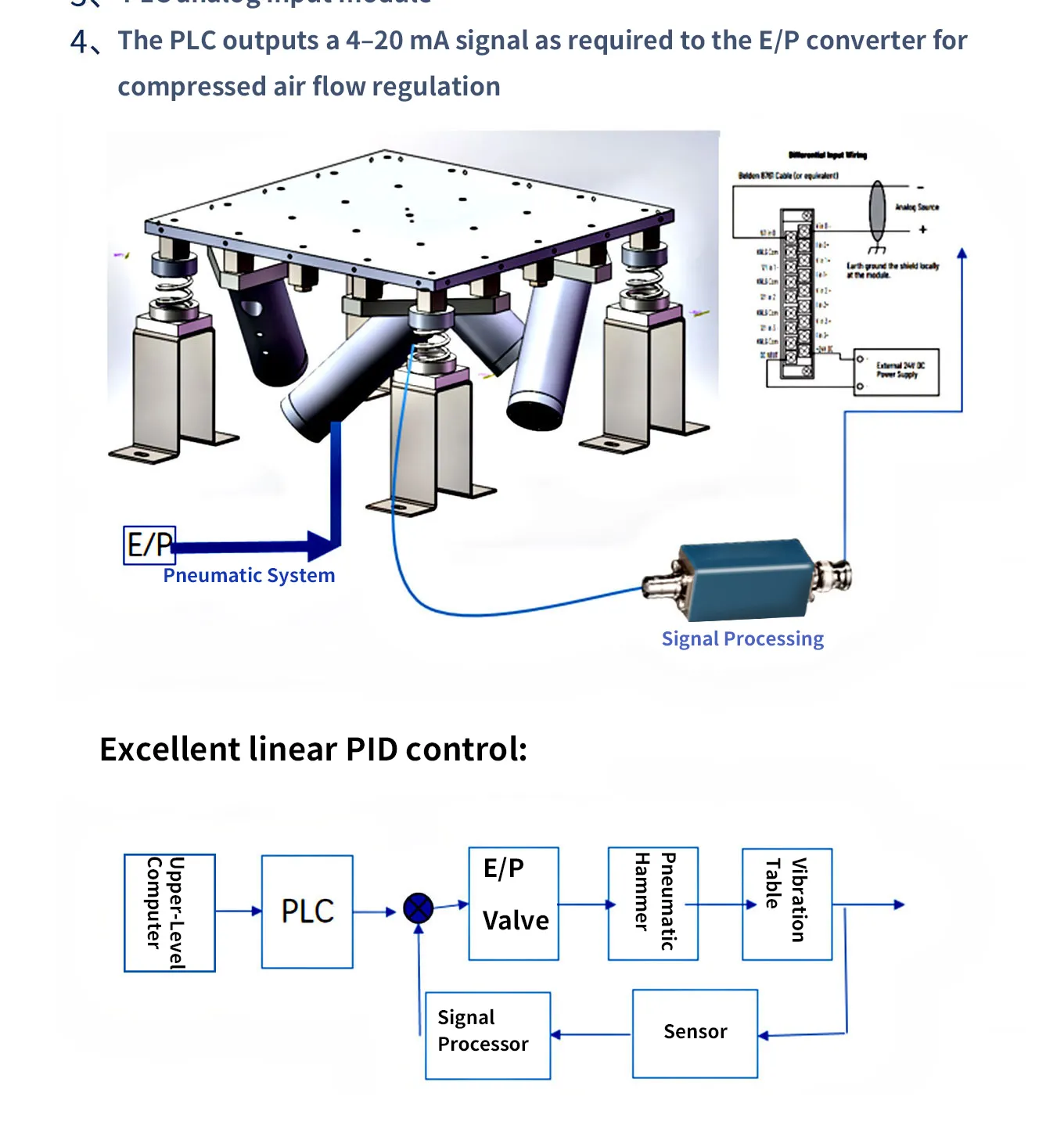

Intelligent Control & Data Traceability for High Test AccuracyThe chamber is fitted with an advanced PLC control system and high-precision sensors, which can realize real-time monitoring and automatic adjustment of pressure, temperature, and vibration parameters. All test data is automatically recorded, stored, and exported in standard formats (CSV/Excel), supporting full-process data traceability. The test accuracy error is controlled within ±0.5°C for temperature and ±0.02 MPa for pressure, meeting strict industrial testing standards.

-

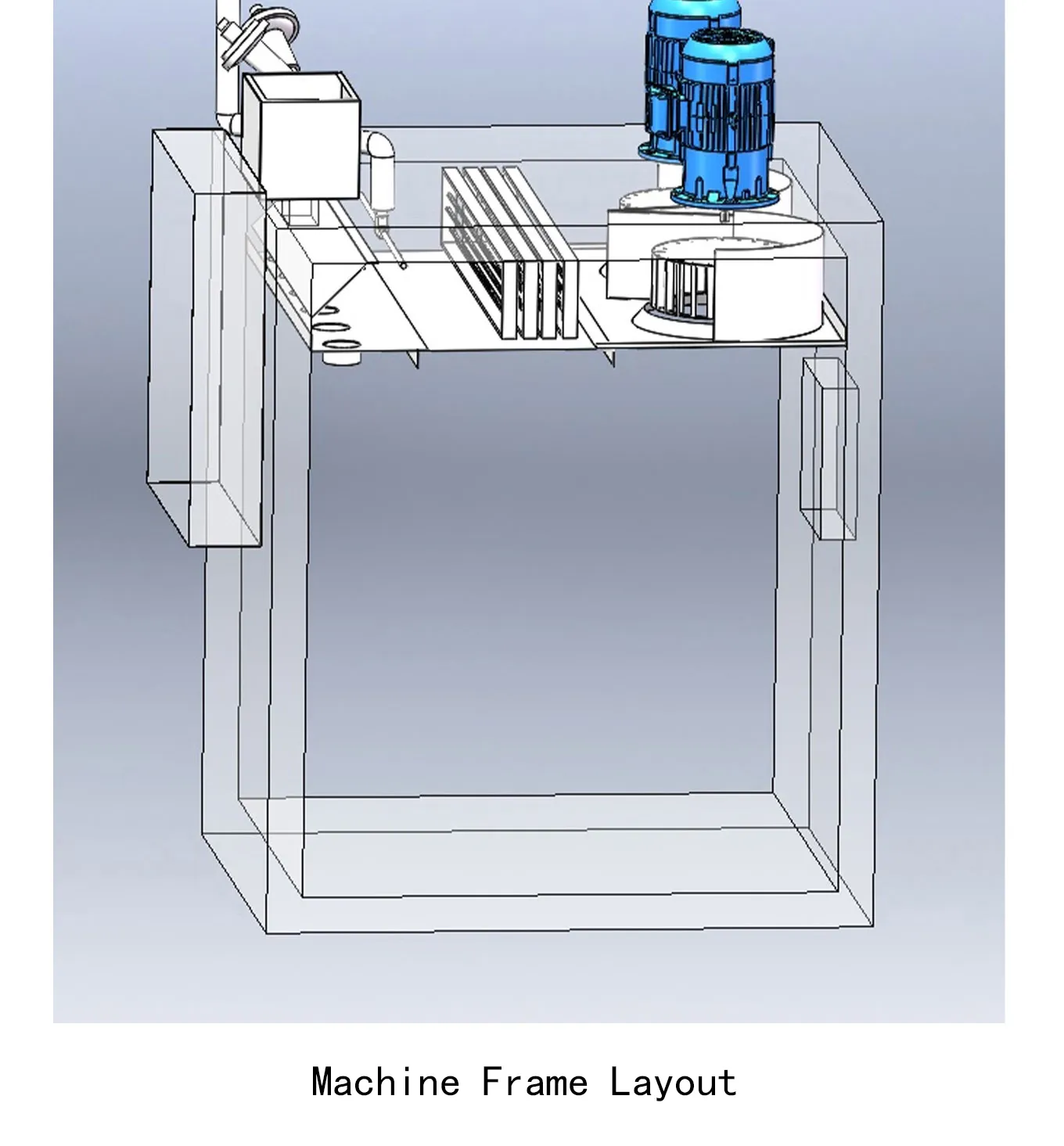

Durable Structure & User-Friendly Design for Long-Term OperationConstructed with high-strength corrosion-resistant alloy materials, the chamber has excellent sealing performance and pressure-bearing capacity, ensuring stable operation even under long-term extreme test conditions. The humanized design includes a touch-screen operation interface, one-click test program startup, and automatic fault alarm functions, which reduces the threshold for operation and maintenance, and lowers the daily management cost for enterprises.

Core Advantages of HALT High-Pressure Accelerated Life Test Chamber

-

Ultra-Fast Failure Detection with Multi-Stress IntegrationThe chamber integrates multiple stress factors including high pressure, rapid temperature change, thermal shock, and vibration, which can simulate the cumulative impact of complex real-world environments on products. This multi-stress coupling technology accelerates the emergence of latent defects by 50–90% faster than single-factor tests, allowing R&D teams to locate design vulnerabilities in days instead of months.

-

High-Pressure Environment Simulation for Special Industry NeedsEquipped with a precision pressure control system, it can simulate high-pressure scenarios ranging from 0.1 MPa to 10 MPa (customizable according to demands). This feature is particularly tailored for products applied in deep-sea exploration, aerospace, and high-pressure pipeline equipment, ensuring the test results are highly consistent with the actual working conditions of such products.

-

Intelligent Control & Data Traceability for High Test AccuracyThe chamber is fitted with an advanced PLC control system and high-precision sensors, which can realize real-time monitoring and automatic adjustment of pressure, temperature, and vibration parameters. All test data is automatically recorded, stored, and exported in standard formats (CSV/Excel), supporting full-process data traceability. The test accuracy error is controlled within ±0.5°C for temperature and ±0.02 MPa for pressure, meeting strict industrial testing standards.

-

Durable Structure & User-Friendly Design for Long-Term OperationConstructed with high-strength corrosion-resistant alloy materials, the chamber has excellent sealing performance and pressure-bearing capacity, ensuring stable operation even under long-term extreme test conditions. The humanized design includes a touch-screen operation interface, one-click test program startup, and automatic fault alarm functions, which reduces the threshold for operation and maintenance, and lowers the daily management cost for enterprises.