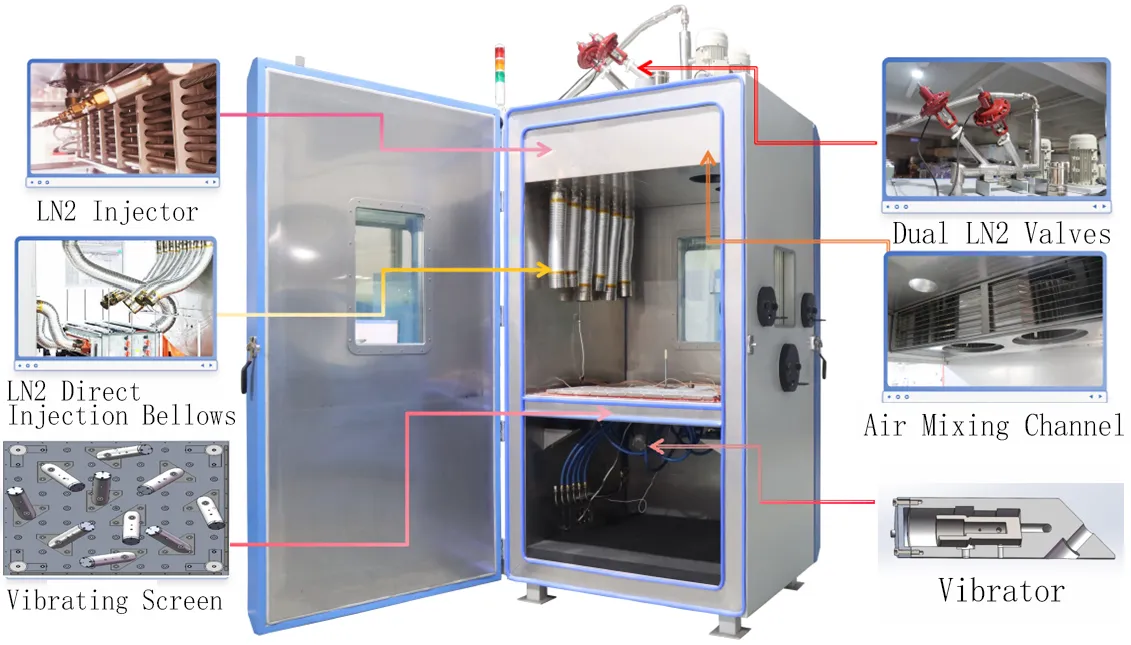

The Highly Accelerated Life Test (HALT) Chamber is an advanced, purpose-built environmental screening system designed not for product validation, but for the rapid discovery of design weaknesses and operational limits. It is a critical engineering tool in the front end of the development cycle, where its value lies in forcing failures to build inherently more robust products.

Unlike traditional test chambers that simulate specific conditions, a HALT Chamber applies a synergistic combination of increasingly severe stresses to accelerate failure mechanisms. Core capabilities include:

-

Extreme Rapid Thermal Cycling: Transitions between extreme high and low temperatures (e.g., -100°C to +200°C) at rates exceeding 60°C per minute.

-

Multi-Axis, High-Frequency Vibration: Utilizing pneumatic actuators or repetitive shock technology to deliver broadband, multi-directional vibration, far beyond typical profile replication.

-

Additional Stressors: Integration of voltage margining, power cycling, and humidity to create comprehensive failure excitation environments.

The philosophy is "find it, fix it." By systematically stepping up stress levels—well beyond expected field specifications—engineers can identify failure modes, fundamental design margins, and the true operational and destruct limits of a product. The result is a dramatic increase in reliability and mean time between failures (MTBF), while significantly reducing costly redesigns and warranty claims post-launch.

In essence, the HALT Chamber is a proactive, forensic tool for resilience engineering. It transforms reliability from a hoped-for outcome into a designed-in, proven characteristic, ensuring products survive not just the expected lifecycle, but the unexpected extremes of the real world.

If you need more information, please contact us now.

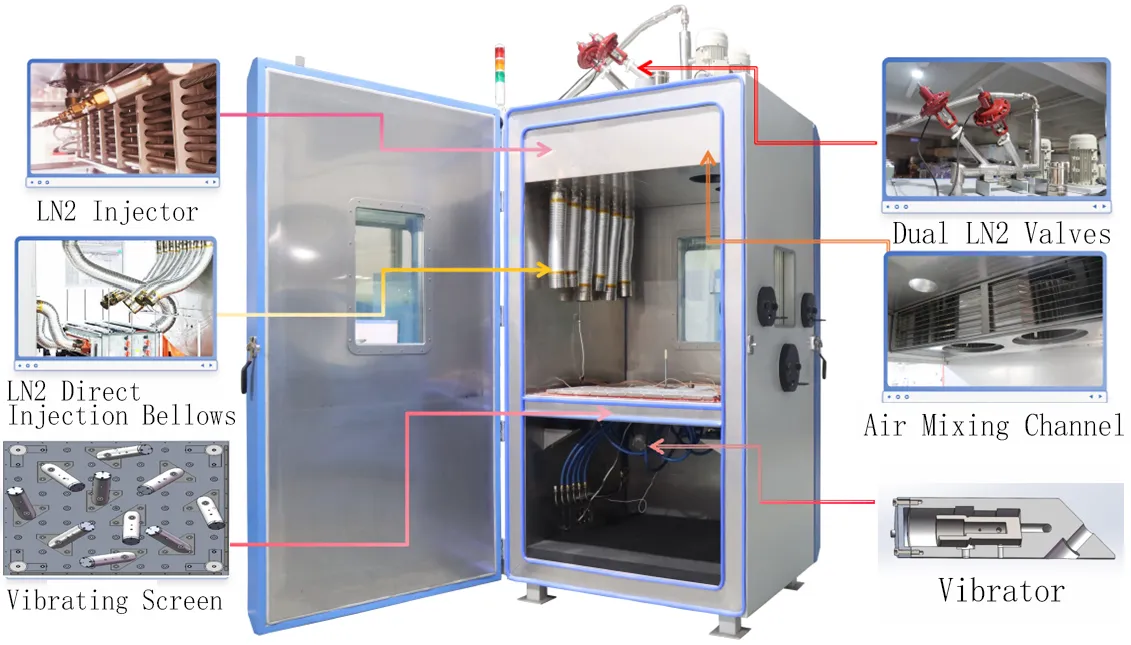

The Highly Accelerated Life Test (HALT) Chamber is an advanced, purpose-built environmental screening system designed not for product validation, but for the rapid discovery of design weaknesses and operational limits. It is a critical engineering tool in the front end of the development cycle, where its value lies in forcing failures to build inherently more robust products.

Unlike traditional test chambers that simulate specific conditions, a HALT Chamber applies a synergistic combination of increasingly severe stresses to accelerate failure mechanisms. Core capabilities include:

-

Extreme Rapid Thermal Cycling: Transitions between extreme high and low temperatures (e.g., -100°C to +200°C) at rates exceeding 60°C per minute.

-

Multi-Axis, High-Frequency Vibration: Utilizing pneumatic actuators or repetitive shock technology to deliver broadband, multi-directional vibration, far beyond typical profile replication.

-

Additional Stressors: Integration of voltage margining, power cycling, and humidity to create comprehensive failure excitation environments.

The philosophy is "find it, fix it." By systematically stepping up stress levels—well beyond expected field specifications—engineers can identify failure modes, fundamental design margins, and the true operational and destruct limits of a product. The result is a dramatic increase in reliability and mean time between failures (MTBF), while significantly reducing costly redesigns and warranty claims post-launch.

In essence, the HALT Chamber is a proactive, forensic tool for resilience engineering. It transforms reliability from a hoped-for outcome into a designed-in, proven characteristic, ensuring products survive not just the expected lifecycle, but the unexpected extremes of the real world.

If you need more information, please contact us now.