Temperature humidity and vibration test chamber (AGREE chamber) mainly for aerospace, aviation, petroleum, chemical, electronics, communications, various electronic components and other scientific research and production units to provide temperature and humidity change environment and electrical vibration stress test conditions, which can be applied to the test at a specified period.

AGREE Chamber

Description

AGREE Chamber Application:

AGREE chamber provides simulated comprehensive environmental conditions for battery, aerospace, aviation, electronics, automobile, quality inspection institutes, research institutes, colleges, universities, and other test units. To shorten the product development cycle, test and verify product quality, improve product quality and reliability, and verify research and development results.

Product Features:

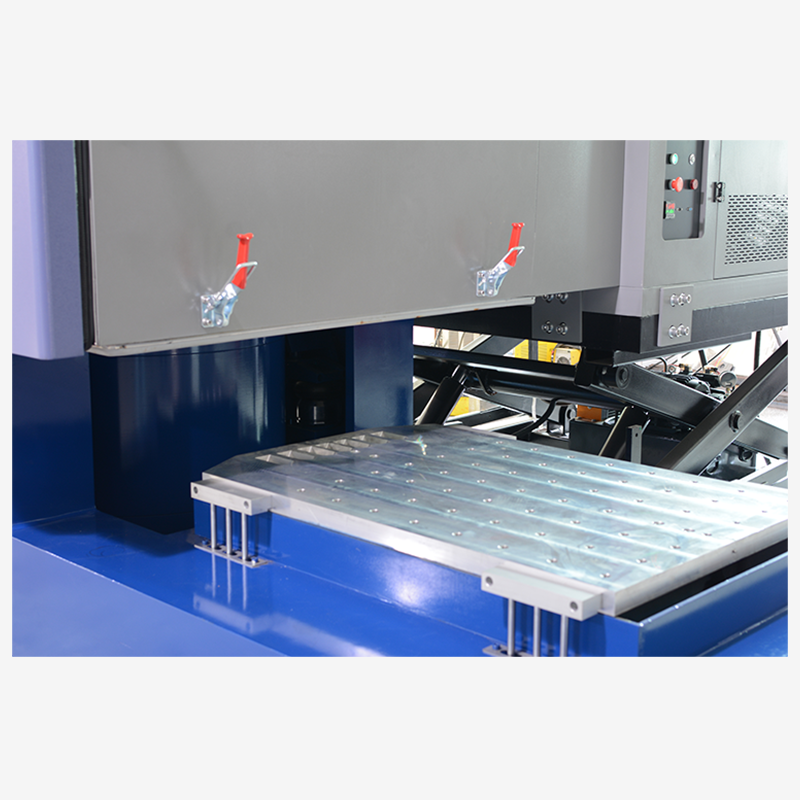

The AGREE chambers are offered in various sizes and accommodate electro-dynamic, mechanical vibration systems. The AGREE Series offers flexibility to be used as a test chamber with or without vibration tables.

*Integrated design of shaking table and temperature chamber;

*Double refrigeration system, excellent refrigeration performance;

*Composite test of the comprehensive environment such as temperature + humidity + vibration;

*A variety of mobile solutions to move the shaker or temperature chamber according to the site;

*Removable test chamber bottom plate design, supporting connection with various electric vibrating tables.

| Specifications of AHV Series AGREE Vibration Chamber. (ATV series means without humidity control.) *Performance is based on ambient temperature +20℃or circulating water temperature +25℃, empty load no specimen. | ||||||||

| Model | AHV | |||||||

| AHV-225 | AHV-408 | AHV-800 | AHV-1000 | AHV-1210 | AHV-1728 | AHV-5832 | ||

| Performance | Temperature range | -20/-40/-70℃to +150℃ | ||||||

| Temp. fluctuation | ±0.5℃ | |||||||

| Temp. uniformity | ±2.0℃ | |||||||

| Temp. deviation | ±2.0℃ | |||||||

| Heating rate | -20℃to +100℃Average 3°C/min in the whole process no load -40℃to +100℃Average 3°C/min in the whole process no load -60℃to +100℃Average 3°C/min in the whole process no load | |||||||

| Cooling rate | +20℃to -20℃Average 1°C/min in the whole process no load +20℃to -40℃Average 1°C/min in the whole process no load +20℃to -70℃Average 1°C/min in the whole process no load | |||||||

| Humidity range | 20%RH~98%RH | |||||||

| Humi. fluctuation | ±2.0%RH | |||||||

| Humi. uniformity | ±3.0%RH | |||||||

| Humi. deviation | ±3.0%RH(>75%RH); ±5.0%RH(≤75%RH) | |||||||

| Frequency Range | 3~5000Hz( Adjustable) | |||||||

| Noise | ≤75dB(A sound level measured at a distance of 1.0 meter when the chamber is at a steady working state.) | |||||||

| Sinusoidal thrust(KG) | 300KG~35T, accept customization | |||||||

| Displacement | See Vibration Test System Details | |||||||

| Maximum load | See Vibration Test System Details | |||||||

| Workspace volume (L) | 225 | 408 | 800 | 1000 | 1210 | 1728 | 5832 | |

| Workspace dimensions (WxHxD)mm | 500 | 600 | 1000 | 1000 | 1100 | 1200 | 1800 | |

| 750 | 850 | 1000 | 1000 | 1000 | 1200 | 1800 | ||

| 600 | 800 | 800 | 1000 | 1100 | 1200 | 1800 | ||

| Exterior dimensions (WxHxD)mm | 1050 | 1160 | 1200 | 1200 | 1300 | 1400 | 2000 | |

| 1600 | 2110 | 2410 | 2400 | 2410 | 2410 | 2400 | ||

| 1950 | 2500 | 2900 | 3100 | 3200 | 3280 | 5340 | ||

| Material | Interior | Matte SUS #304 Stainless Steel Plates | ||||||

| Exterior | Powder Coated Carbon Steel Plates | |||||||

| Insulation | Hard Polyurethane Foam Insulation and Glass Wool | |||||||

| System | Refrigeration | Copeland Full -Hermetic compressor or German BITZER Semi-Hermetic compressor Zero Ozone Depletion Potential (ODP) Refrigerant – R404A / R23 | ||||||

| Cooling method | Water-cooled/air-cooled | |||||||

| Controller | LED true color touch screen controller; multiple language options | |||||||

| Lifting method | The machine can automatically lift and move left and right, and the height can be adjusted according to the vibration level. | |||||||

| Standard test | GB/T 2423.10-2019. GB/T 2423.11-1997 . GB/T 2423.12-1997. GB/T 2423.13-1997. GB/T 2423.14-1997. GB/T 2423.35-2019. GB/T 2423.36-2005. GB/T 2423.48-2018. GB/T 2423.49-1997 . GB/T 2424.22-1986. GB/T 2424.24-1995 | |||||||

| Security measures | a.Heater Dry-Burning Protection Switch; b.Heater Over-Current Circuit Breaker; c.Humidifier Dry-Burning Protection Switch; d.Humidifier Over-Current Circuit Breaker; e.Humidifier Low Water Level Protection; f.Compressor Over-Heat Protection Switch; g.Compressor Over-Current Protection Switch; h.Compressor High Voltage Protection Switch; i.Circuit Breaker; j.No Fuse Breaker; k.Over-Voltage and Phase Loss Protection Switch; l.Water Tank Low Water Level Warning | |||||||

| Standard accessories | Ø50mm lead hole 2x; casters 4x; stainless steel sample holder 2x;1x transparent electric heating film insulating glass observation window; 1x lighting lamp | |||||||

| Electrical supply | AC 380V (1±10%), (50±0.5)Hz. 3 Phase. 4 Wire, plus earth wire/other power | |||||||

| ▲Custom options available | ||||||||

You must be logged in to post a review.

Reviews

There are no reviews yet.